An allergic reaction is an overreaction of the immune system to a certain, often harmless substance. It then forms antibodies, so-called immunoglobulins. This body reaction provides the basis for the functioning of the ImmunoCAP™.

The tool measures the specific immunoglobulin E (IgE). In this way it is possible to determine sensitization at an early stage, often before patients develop clinical symptoms. “With ImmunoCAP™ it is possible to test sensitization to significantly more than 500 different allergens,” says Magnus Askvid, Manager Production Engineering at Thermo Fisher Scientific.

The test principle

For the IgE-test, the physician first takes blood from the patient. The obtained serum or plasma is added to the ImmunoCAP™ Allergen in a laboratory system and the number of the respective antibodies is determined. Sensitization to an allergen is confirmed or ruled out as follows.

Long-standing partner

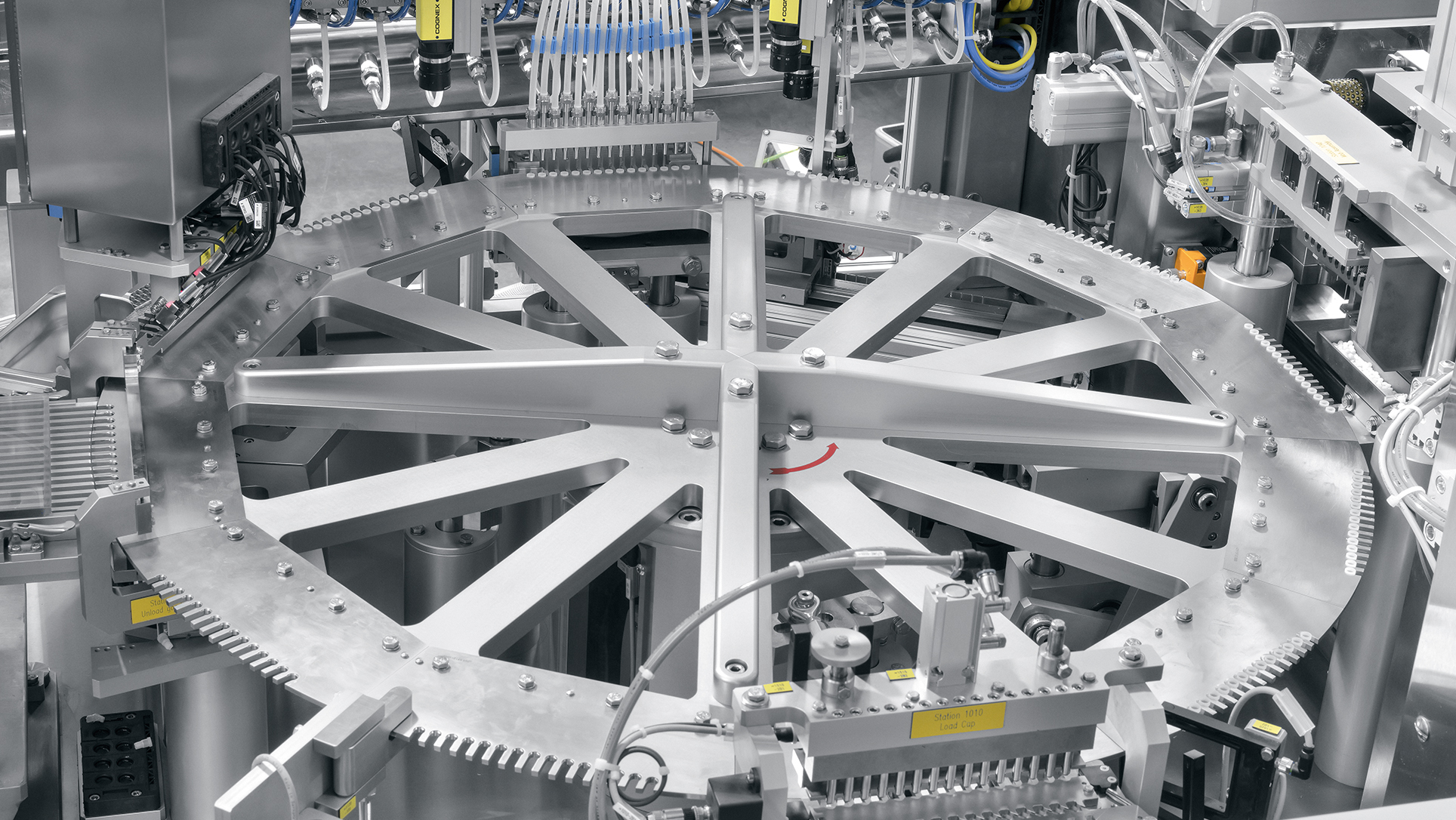

Harro Höfliger has been supporting Thermo Fisher for more than thirty years with the product assembly of the ImmunoCAP™ test dispenser. At the end of 2017, the fifth machine was delivered to Uppsala.

The individual parts of the ImmunoCAP™ test dispenser are fed as bulk material to two coupled machines. Then the insertion of the sponges takes place which are punched in parallel from nonwoven material soaked in liquid. A camera controls the presence and position of the punched parts. Subsequently, the pass-caps are moistened with buffer liquid. This is again followed by an optical dosage control. Any fail-parts will be rejected. At another intermittent machine a camera checks the plastic tubes for damage before they are filled with caps. A slight vibration of the tube after insertion ensures that the caps slide into each other easily. Furthermore, a mechanical fill level control checks the tubes for correct filling. In the last assembly step, the caps, which are fed via a vibratory feeder, are fitted.

Links

MARKET SEGMENTS

Diagnostic Products

Customized solutions for the production of highly precise systems for diagnostic purposes