Great deal of dexterity in handling

There are many active ingredients which can only be preserved in aqueous solutions for a short time. Particularly with thermally sensitive materials, freeze-drying (lyophilization) into pellets is a method used to achieve storable formulations. After flash freezing and dehydration under high negative pressure, a spherical, porous framework of active ingredients and excipients remains – with low density and a large, highly hygroscopic surface by comparison.

Lyo bead pellets are well suited for parenteral products such as vaccines due to their high rate of dissolution. Even for new diagnostic tools, such as lab-on-a-chip systems, they are ideal due to their storage stability. However, the fragile structure of the lyophilisates requires a great deal of dexterity in handling: Typical 0.5 to two-millimeter pellets are prone to mechanical abrasion and compression, become electrostatically charged, and must be processed at low humidity. Moreover, the small dosing amounts usually don’t allow volumetric dosing.

Flexible and gentle product treatment

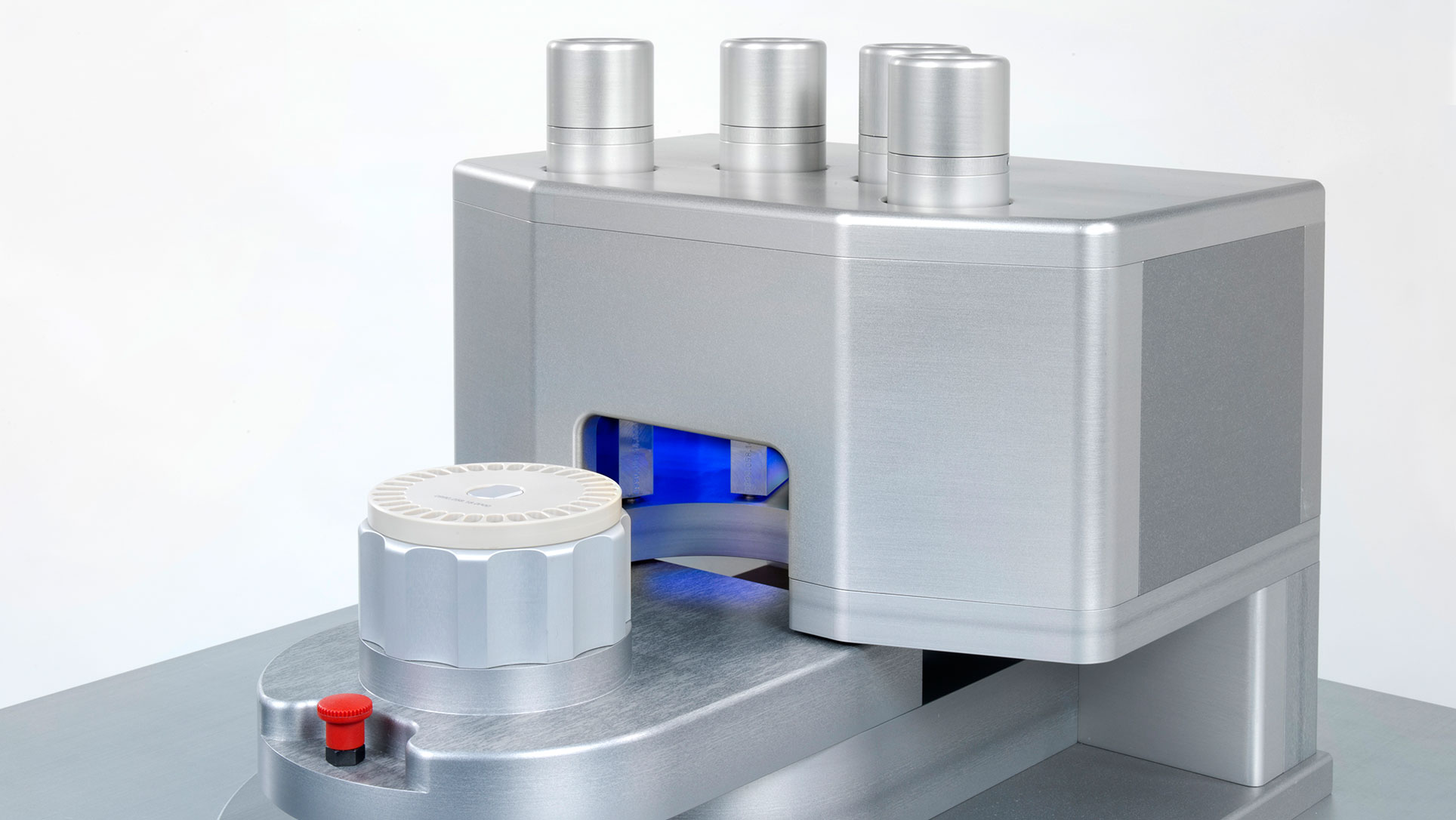

Harro Höfliger’s entirely pneumatic Lyobead Dispenser can handle pellets with these properties. The pellets are fed in bulk, then separated non-destructively by dry air, precisely counted, and gently placed in the container. By eliminating mechanical transport solutions, the lyophilisates are safely conveyed and accurately dosed.

In addition to gentle processing, flexibility is a top priority. Depending on the degree of automation and number of dosing stations, single and multiple dosing is possible – including combinations of products into a variety of containers. The most common include vials, discs, cartridges or titer plates. The dosing speed per station is up to 30 pellets per minute, depending on the product properties.

Further benefits of the compact, low-maintenance dispenser are its ease of use and cleaning, as well as good integration capabilities in lines. An upstream sorting station rejects damaged pellets or pellet conglomerates, guaranteeing the highest product quality.

Links

MARKET SEGMENTS

Diagnostic Products

Customized solutions for the production of highly precise systems for diagnostic purposes.

Machines & Technology

Lyobead Dispenser

Gentle processes: Air flow dosing of sensitive lyophilized pellets (semi-automatic).