Modu-C CS

A wide range of applications: Highly efficient, commercial capsule filling on a small scale

Description

Whether segment turret, in-process-control (IPC) or 100% weight control – sophisticated, robust processes guarantee a smooth, reliable and transparent production. With the help of individual feeding and dosing technology, the Modu-C CS achieves optimum results even when handling very small product quantities and complex rheological properties. The trolley system provides maximum flexibility, modularity and short downtimes thanks to fast dosing system changeovers.

Benefits

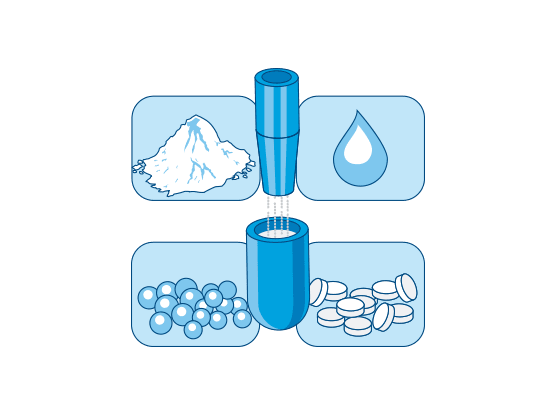

- Dosing of various powders and pellets

- Suited for “engineered particles”, spray-dried powder, pure active ingredients and more

- Integrated 100% gross weight control

- Short set-up times

- Product-saving processes

- Intuitive operator control and easy cleaning

- PAT-systems (Process Analytical Technology)

- In-process control (IPC)

Technical data

- Output: 43,500 capsules/h

- Formats: all commonly used capsule sizes (000 up to 5)

- Dosing systems: drum filler, tamping pin, pellet, dosator, tablet, mini tablet, liquid

Final products

- Capsules with single dose or fixed dose combinations

Periphery

- Empty capsule feeding (Convey-C)

- Customized product feeding

- Metal detector

Machine features

Trolley concept

The patented trolley system enables a quick change of the dosing system: whether powders, pellets, tablets, mini tablets or liquids – the next dosing process is already standing by. Short set-up times, fast cleaning, maximum productivity. Process changeovers by means of plug and play.

Capacitive weight inspection

The innovative, integrated 100% gross weighing system checks and sorts all capsules produced. The innovative system thus sets new standards. 100% gross weighing can be combined with an IPC station.

Combination filling

Different dosing systems enable combined filling with up to three products such as powders, pellets, tablets, mini-tablets or liquids. The filling of capsules into capsules is also possible.

IPC Station

Optionally, an integrated IPC station ensures precise weighing of the individual dosing quantities (net weights). It can be used for both statistical capsule weighing and adjustment of the AMV sensor.