Modu-C HS

Efficient with high speed: Compact capsule filling machine for highest productivity

Description

The Modu-C HS is especially designed to meet highest requirements in capsule production. The patented trolley system allows a rapid change of the dosing systems for powder, pellets, tablets and mini-tablets. The machine is impressive with its easy operation and minimal setup and downtimes during format changes and cleaning.

Benefits

- Flexibly expandable with the patented dosing trolley system

- PRP function (person reduced production) Calibration bar to detect deformed capsules, exhaust function of deformed capsules, differential pressure measurement to inspect the presence of capsule bottoms, capsule closure inspection and single elimination of bad capsules

- Minimum setup time

- Easy operation and cleaning

- Minimum product loss with no-cap-no-fill function

- Supported by Pharma Service

Technical data

- Output: Up to 200,000 capsules/h

- Formats: All common capsule sizes

- Dosing units: Roller, tamping station, pellet, tablet, mini-tablet, capsule-in-capsule and liquid

Final products

- Capsule production for combination and single dosages

Periphery

- Empty capsule feeding (Convey-C)

- Customized product feed

- In-line and online weight determination: Static gross/net inspection, 100% gross/net inspection, 100% net inspection via capacitive AMV sensor for minimal quantities dosing

- Capsule dedusting

- Metal detector

- Recycling solution for recycling raw materials (RecyCap)

Machine features

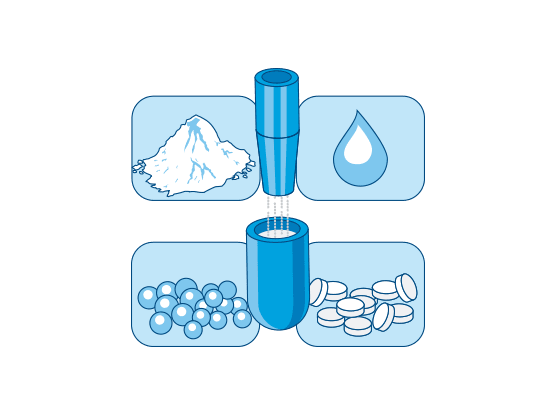

Trolley concept

The patented dosing trolley system allows the operator to quickly change the dosing method: Whether powder, pellets, tablets, mini-tablets or liquid – the next dosing process is already set up. Short setup times, fast cleaning, maximum productivity. Plug-and-play options for the process change.

Capacitive weight inspection

Fastest process analytics through mass acquisition: The mass-specific AMV sensor allows for 100% inspection during the dosing of powders and pellets. The PAT method is independent of the target vessel.

Combination filling

Various dosing systems allow combination fillings with up to three products such as powders, pellets, tablets, mini-tablets, powder blends, active ingredients or liquids. It is even possible to fill capsules into capsules.

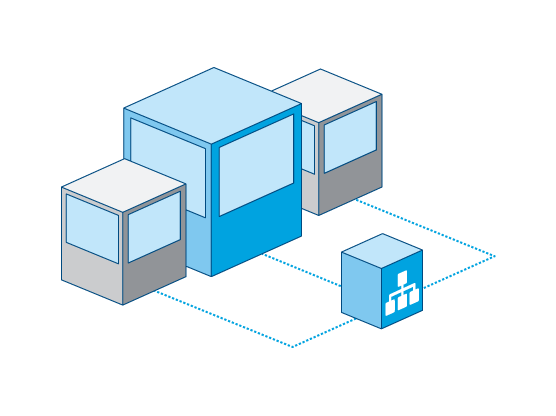

Peripheral network

Standard interfaces (MES, ActiveDirectory, OPC, …) allow the customer-specific peripherals to communicated with the IT network of the Harro Höfliger systems.