Modu-C MS

Powerful at mid-speed: The versatile capsule filling machine in medium power range

Description

The Modu-C MS is especially designed for reliable and flexible capsule production. The patented trolley system allows a rapid change of the dosing systems for powder, pellets, tablets, mini tablets and liquid. The machine is impressive with its ease of use and minimum set-up and down times during format changes and cleaning.

Benefits

- Flexible with replaceable dosing trolleys

- PRP-function (Person reduced production)

- Calibration bar to detect deformed capsules, exhaust function of deformed capsules, differential pressure measurement to inspect the presence of capsule bottoms, capsule closure inspection and single elimination of bad capsules.

- Minimum set-up time

- Easy operation and cleaning

- Minimized product loss with No-Cap-No-Fill function

Technical data

- Output: Up to 100,000 capsules/h

- Formats: All common capsule sizes

- Dosing units: Drum, dosator, tamping station, pellet, tablet, mini-tablet, capsule-in-capsule and liquid

Final products

- Capsule production for combination and single dosages

Periphery

- Empty capsule feeding (Convey-C)

- Customized product feed

- In-line and online weight determination: Static gross/net inspection, 100% gross/net inspection, 100% net inspection via capacitive AMV sensor for minimal quantities dosing

- Capsule dedusting

- Metal detector

- Recycling solution for recycling raw materials (RecyCap)

Machine features

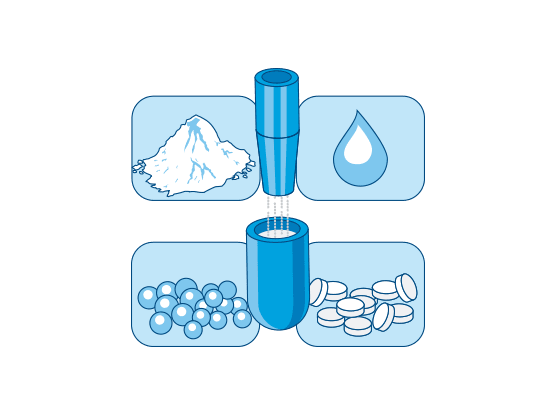

Trolley concept

The patented dosing trolley system allows the operator to quickly change the dosing method: Whether powder, pellets, tablets, mini-tablets or liquid – the next dosing process is already set up. Short setup times, fast cleaning, maximum productivity. Plug-and-play options for the process change.

Capacitive weight inspection

Fastest process analytics through mass acquisition: The mass-specific AMV sensor allows for 100% inspection during the dosing of powders and pellets. The PAT method is independent of the target vessel.

Combination filling

Various dosing systems allow combination fillings with up to three products such as powders, pellets, tablets, mini-tablets, powder blends, active ingredients or liquids. It is even possible to fill capsules into capsules.

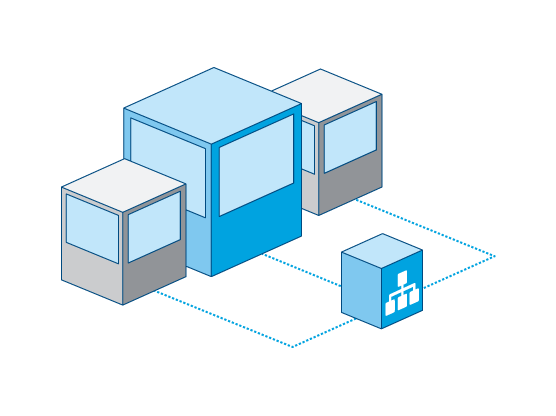

Peripheral network

Standard interfaces (MES, ActiveDirectory, OPC, …) allow the customer-specific peripherals to communicated with the IT network of the Harro Höfliger systems.