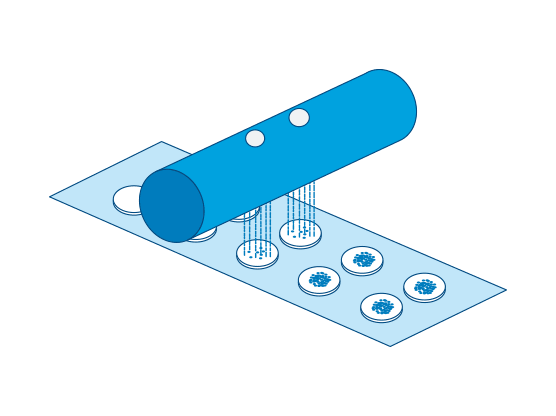

Disc Filler

Efficient: Simultaneous filling of discs for dry powder inhalers (semi-automatic)

Description

The Disc Filler fills DPI discs with any number or shape of cavities in a single operation. Only exchange two format parts for a quick format or product change at any time. The Disc Filler can be integrated into automated machines to fill, assemble and package disc-base inhalers and increase the output by adding additional filling heads.

Benefits

- Fast, simultaneous filling of DPI disc cavities

- Easy format and product change

- Precise micro-dosing of a variety of powders

- Adjustable filling quantity

- Gentle powder handling to prevent abrasion and clogging

- Suitable for cavities of varying geometries and arrangements

Final products

- DPI Discs

- Diagnostic applications

- Lab automation

Machine features

Filling discs

Preformed cavities are positioned in the product working fixture. Minimum quantities of powder are filled using a membrane filling method with synchronously working fill positions. This ensures a fast and equal filling for all disc cavities.

Micro-dosing

Various dosing methods allows the dosing of minimal quantities of powder. Depending on the individual powder properties different filling methods such as membrane filling, tamping pin, dosator or drum filling are applicable.