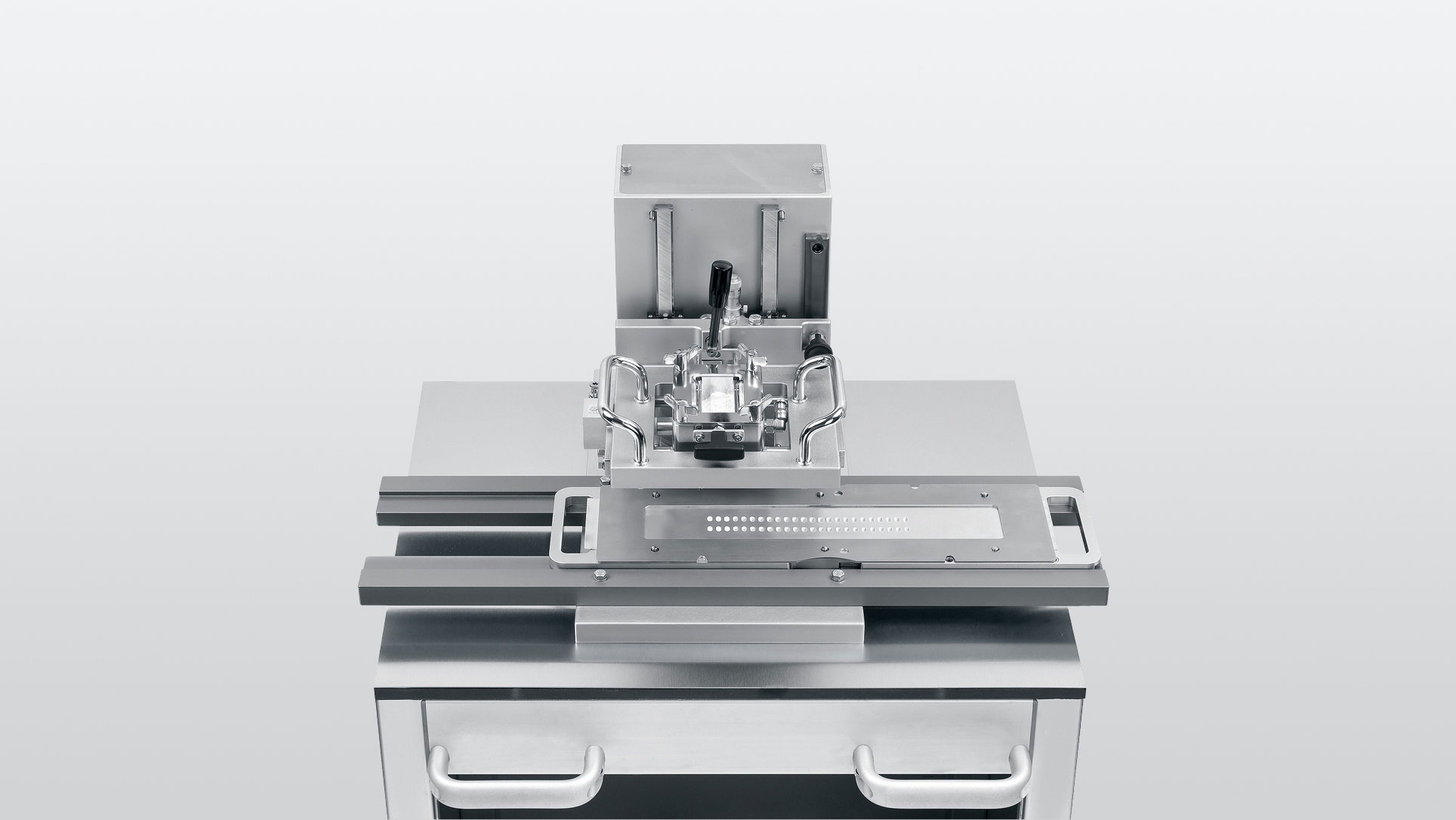

Membrane Filler TT

Table top: Lab table unit to completely fill minimum quantities of powder into cavities

Description

The membrane technology allows cavities of any form and geometry to be filled 100%. This allows you to quickly and reliably test the process capability of minimum quantities of fine-grain powder – a simple entry into laboratory testing of powder samples. The unit can be easily expanded for series production.

Benefits

- Ease of use ensures a rapid filling process

- Clean dosing with no powder residue outside of the container

- Expandable for batch series and production standard

- Universal system for all types of cavities

- Suitable for verifying dosing capability and production of minimum sample quantities

Technical data

- Dosing volume: approx. 20 mm³ - approx. 1000 mm³

- Dosing range: 10 - 5000 mg*

- Particle size: as little as 1 µm

* For reference density of powder of 0.5 mg per mm³

Final products

- Inhaler products

- Diagnostics

- Chemical-technical applications

- Care products

Machine features

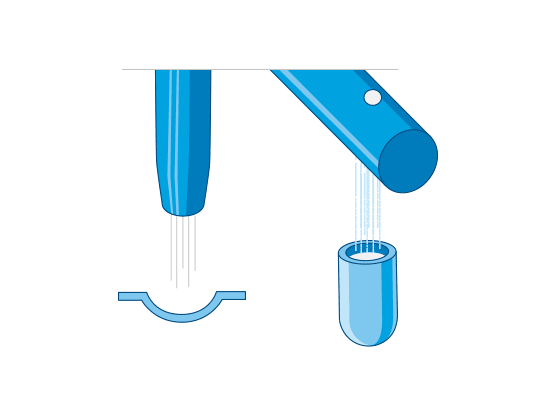

Micro-dosing

Various dosing methods allows the dosing of minimal quantities of powder. Depending on the individual powder properties different filling methods such as membrane filling, tamping pin, dosator or drum filling are applicable.

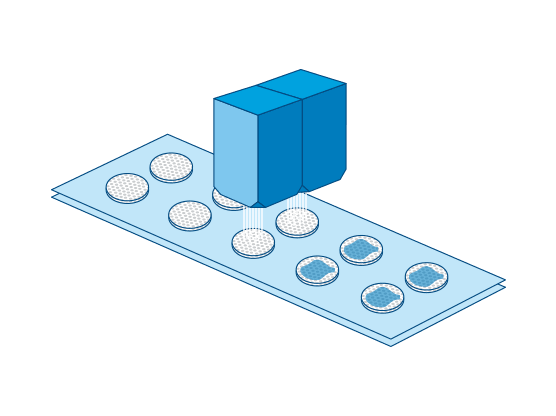

Filling blisters

The powder filling module can be equipped with a drum filler or with a membrane filler. The drum filler produces partially filled cavities whereas membrane filler is filling the blister cavity to 100%.