SDM

Practical: Auger dosing unit for powder dosing, suitable for pharmaceutical applications (semi-automatic)

Description

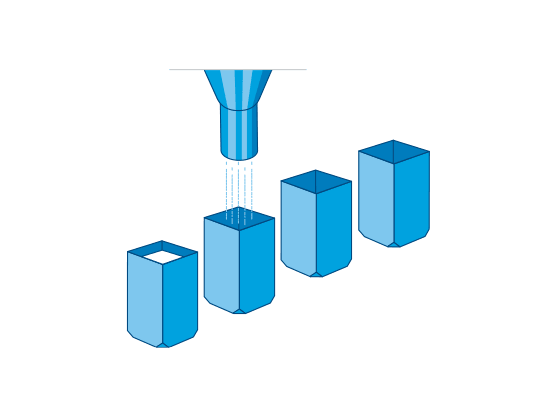

The SDM auger dosing unit fills vials, reservoirs and cartridges with powder. Its purpose is to verify the dosing of the powder and to produce the smallest sample quantities for lab tests. The dosing range can be adjusted variably with servo technology. The SDM can be operated as a standalone unit or as a setup model.

Benefits

- Separate drives for stirrer, cross feeding and dosing auger

- Tool-free replacement of parts in contact with the powder

- Optional tendency regulation based on the “fill-to-weight” principle with gravimetric scale

- Optional sterilizable parts in contact with the product

- Optional sealing system to prevent the powder from spilling out

- Optional integrated ionization of the dust extraction

Technical data

- Dosing volume: approx. 20 mm³ – approx. 1000 mm³

- Dosing range: 10 – 5000 mg*

- Particle size: 1 µm and higher

* At a reference density of the powder of 0.5 mg per mm³

Final products

- Cartridges

- Powder reservoirs

- Devices

- Vials

Machine features

Filling cartridges and discs

Prepared cavities are placed in the product mounts and transported to the filling station. Minimum quantities of powder are filled at several filling stations within a specific clocking sequence. Dosing units with multiple, synchronized fill positions are used for higher outputs.

Filling the reservoir

Some dry powder inhalers include a powder reservoir for a pre-defined number of dosages. Generally, the defined quantity of active ingredients is filled using an auger filler. Several filling spaces can be integrated to increase the output.

Fill-to-weight

A gravimetric scale calculates the weight during the filling process. Once filling approaches the target weight, the output quantity is reduced and the filling process is continued via fine dosing until the pre-defined target weight is reached exactly. Fill-to-weight allows quick and precise dosing.