FLP

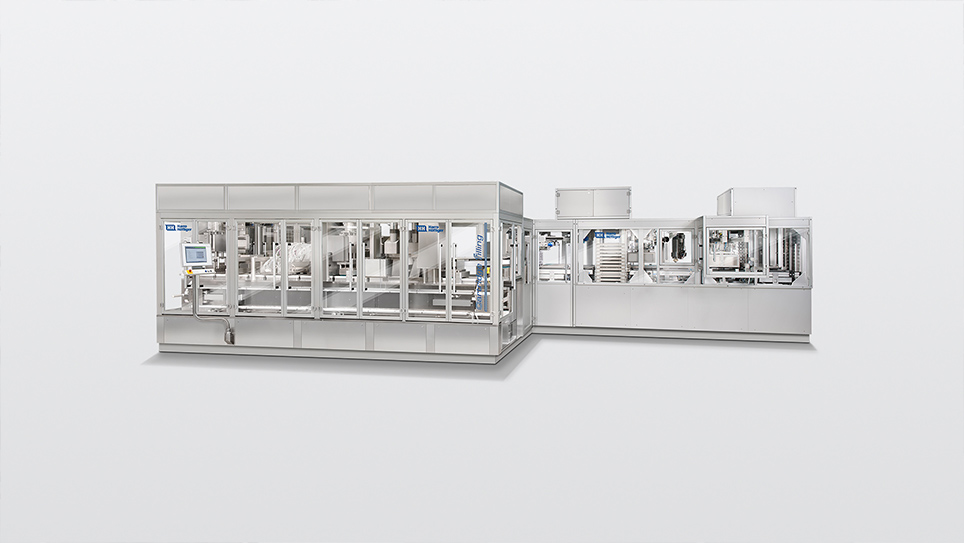

Fully automatic: Length-wise plate transport to assemble and fill powder inhalers (intermittent)

Description

FLP is a production platform for inhaler products. The standard platform makes it possible to easily integrate complex technologies, processes and assembly tasks. This filling machine makes it possible to fill several panels at the same time, while also assembling complex inhalers with unit dose cartridges or multi-dose discs.

Benefits

- Standardized platform to integrated technologies and processes

- Precise product transport per tray

- Ideal for inhaler production with complex dosing, assembly and inspection processes

- Easy to link to other technology platforms and packaging machines

Final products

- Inhalers with unit dose cartridges

- Inhalers with multi-dose discs

Periphery

- Tray handling

- Packaging machines for shipping boxes

Machine features

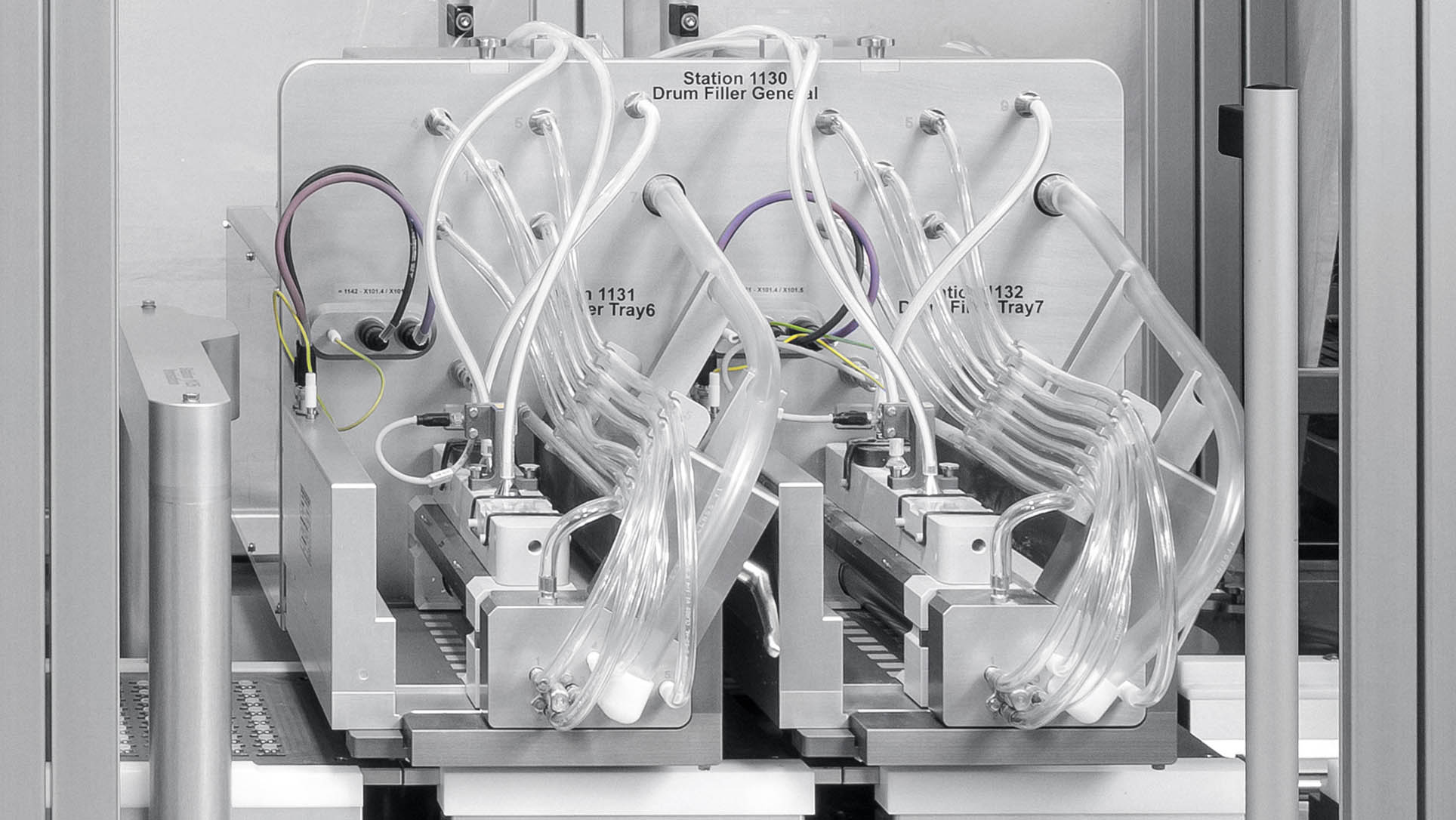

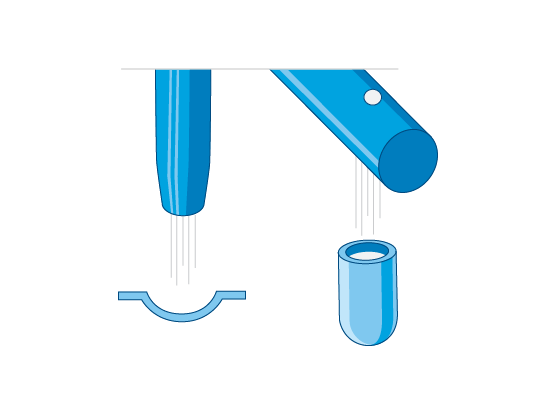

Micro-dosing

Various dosing methods allows the dosing of minimal quantities of powder. Depending on the individual powder properties different filling methods such as membrane filling, tamping pin, dosator or drum filling are applicable.

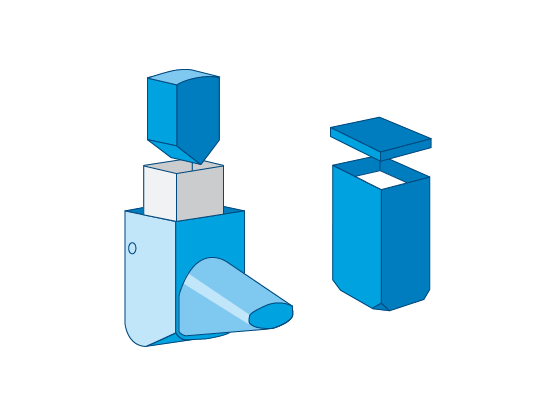

Device assembly

The assembly processes designed by Harro Höfliger meet simple and complex assembly tasks alike – from inserting reservoirs into inhalers or closing cartridges to the final assembly of DPI inhalers, auto-injectors and pens.

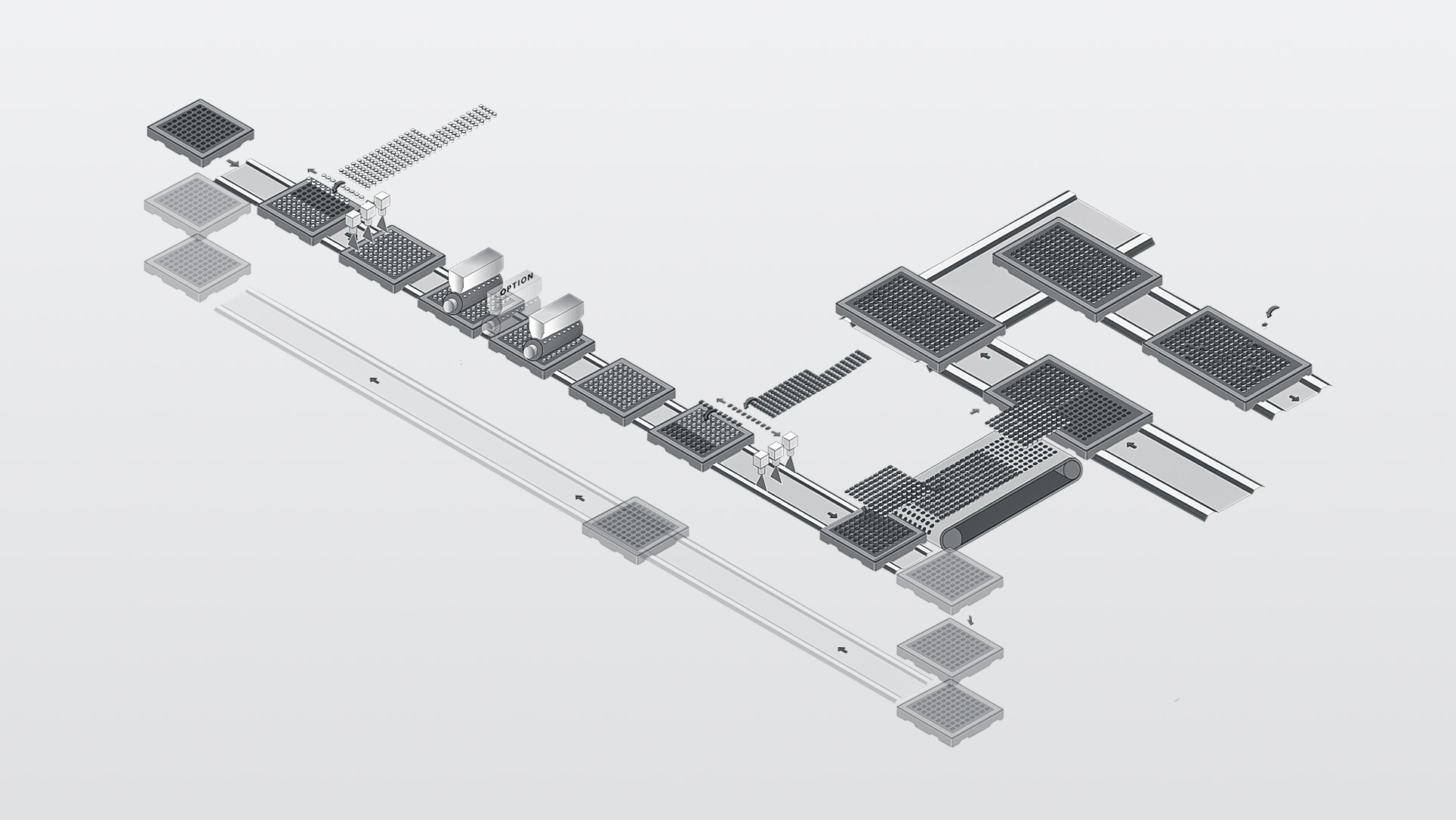

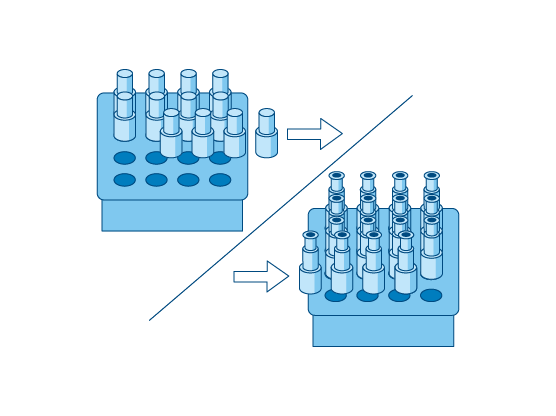

Tray handling

Trays serve to transport sensitive products. Harro Höfliger offers comprehensive solutions to load and unload trays in complete lines, for assembly projects for example. Available systems include a variety of format and performance classes for optimum synchronization.

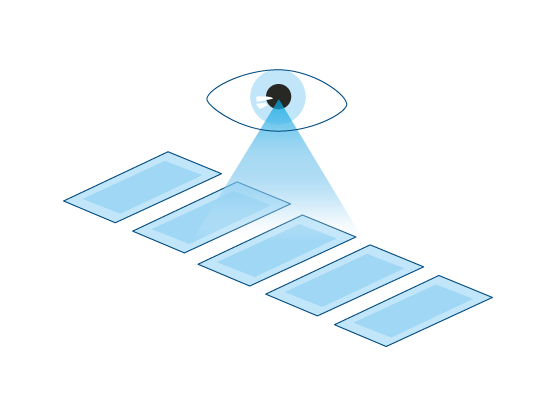

Final inspection

The final inspection of assembly products is essential for product safety and functional capability. When administering active ingredients, precise portioning of the medication is crucial. The inspections test for triggering, discharge or leak tightness. Force, path and torque of the test are pre-definable.

Applications

Administration of insulin using DPI inhalers

Powder inhalers help diabetes patients: For the MannKind Corporation located in the United States, Harro Höfliger engineered and constructed two filling and assembly systems for dry powder inhalers.