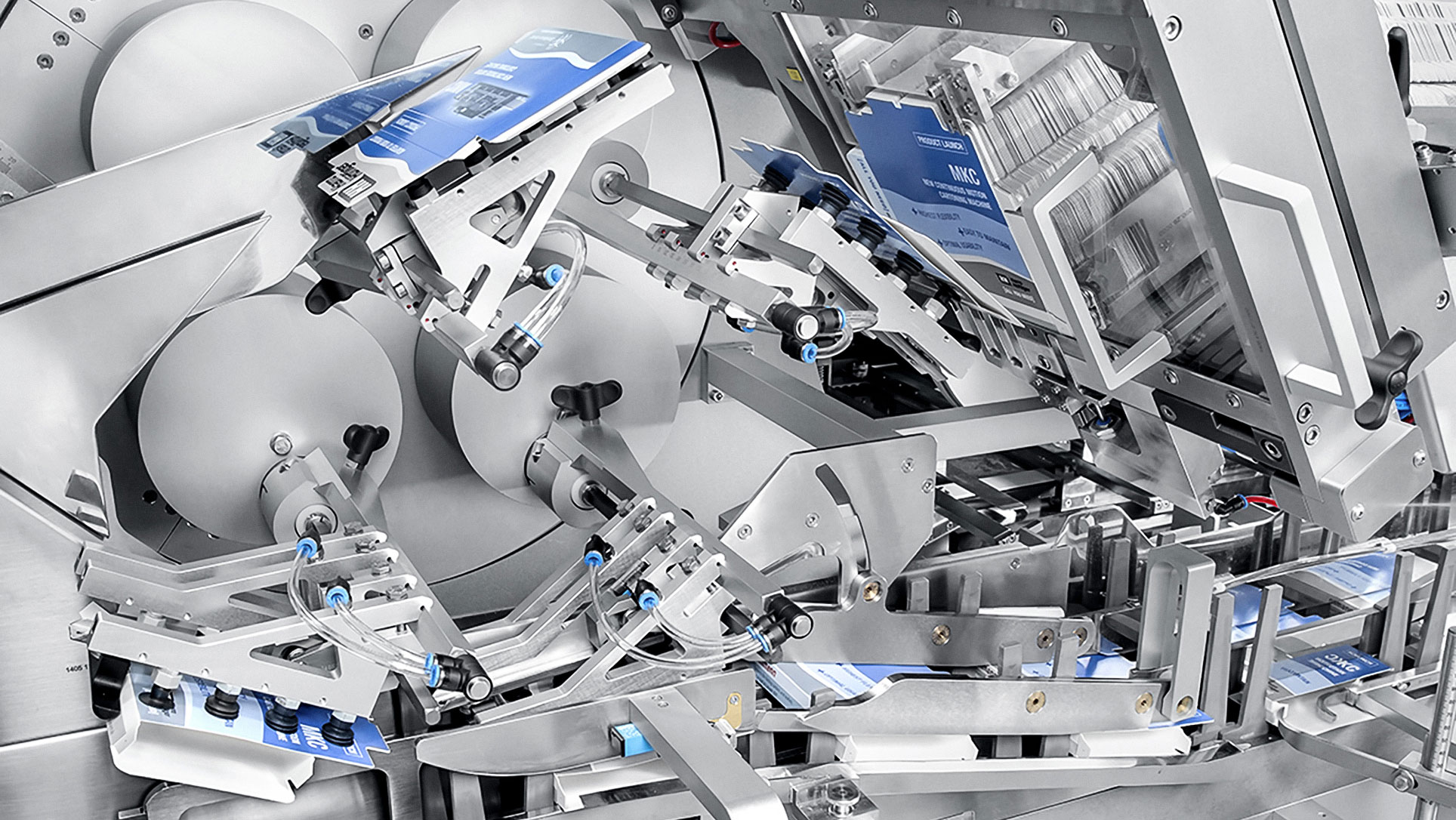

MKC

Productive: The flexible cartoning machine with high output (continuous)

Description

Thanks to different modules for product feeding, product transport, product insertion and folding box closure, the cartoner MKC can be configured in an optimal way to meet customer requirements. With various closure types, product infeeds and customized solutions available, the MKC can be flexibly adapted. This horizontal cartoning machine ensures a safe and gentle transport, loading and insertion of the products into the folding box (side-loading). Even existing top-loader applications can be easily adapted to the horizontal MKC, by minor adjustments to the folding boxes, e.g. top-opening cartons for product presentation at its best.

Benefits

- Highest flexibility as a result of modular design for solutions tailored specifically to customer needs.

- Ease of use with movable touch panel and state-of-the-art visualization technology, low construction and ergonomic machine design for optimal accessibility.

- Ideal range of applications with highly dynamic servo drives and overload protection at all safety-relevant machine functions.

- Set-up of all common folding box closure variants in large format range (adjustment options with reproducible settings) and

- customized closure options, plus up to two closure variants on one machine

- Ability to add on various feeding systems and to expand the system with serializing functions

- Product insertion from the rear (side-loading) ensures a clear machine front and optimal accessibility of the packaging area

Technical data

- Output MKC 15″: up to 100 folding boxes/min.

- Output MKC 7,5″: up to 200 folding boxes/min.

- Output MKC 5″: up to 300 folding boxes/min.

Final products

- Bottles

- Pouches

- Blisters

- Dressing and Patches

- Vials

- Customized solutions

Periphery

- Assembly systems

- Web processing machines

- Film forming machines

- Dosing and filling machines

- Inspection systems

- Serialization

Machine features

Product feeding

Product feeding plays a critical role in packaging machines. Harro Höfliger has a large repertoire of product handling systems. The feeding technology is configured individually depending on the requirements of the project and adjusted to the particular specifications.

Bottle supply

Feeding bottles at high speeds requires a precisely tuned motion sequence. For the cartoning process, bottles are separated and a pocket wheel rotates them from standing to laying position. This process must be executed sensitively to prevent the bottle from breaking.

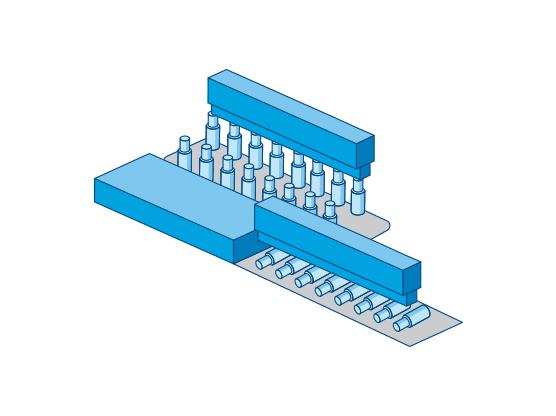

Pick & Place

Products are automatically taken up using vacs, grippers or tongs and accurately transferred. This can be performed in a linear or swivel movement. To increase the output, these systems can be set up at multiple locations so as to perform loading and unloading tasks at the same time.

Serializing

Our packaging machines can be easily equipped with serializing processes for the benefit of quality assurance and to increase protection from counterfeiting medicine. In the process, folding boxes are each marked individually and recorded by an image inspection system.

Applications

side-loading/top-opening

Packaging products quickly and attractively – horizontal cartoning units are a convenient solution for safe, customer-friendly packaging of several components in top-opening boxes.