PPH

Vertical filling: Four-edge seal bag machine for the pharmaceutical industry (intermittent)

Description

The pharmaceutical bag machine PPH produces flat bags and fills them with powder and bulk goods. The packaging film is printed in the machine and linearly transported to the three-edge sealing bag for further processing. The bags are delivered in the round motion machine, following by dosing with a 100% weight inspection as well as final sealing. The bags are fed to the downstream cartoning machine via a stacking station and are packaged specifically by format into folding boxes.

Benefits

- Modern construction in GMP-appropriate design

- Connection to lines and fully automatic production

- Separate monitoring of all quality-relevant process steps

- Completely protected production room

- The ability to manufacture product variants and patient-specific preparations

- Integration of micro-dosing systems for bulk goods, powder and liquid

- Fast product delivery through parameterized batch release

Technical data

- Output (PPH 80/160/300): 80/160/300 bags/min

- Bag format area approx. (mm): L: 60–120, B: 50-70

- Dosing range: 1 mg – 500 mg/bags at three dosing stations

- Tendency regulation of the dosing syste

Final products

- Four-edge sealing bags with pharmaceutical media

Periphery

- Packaging machines

- Labeling systems

- Control systems

Machine features

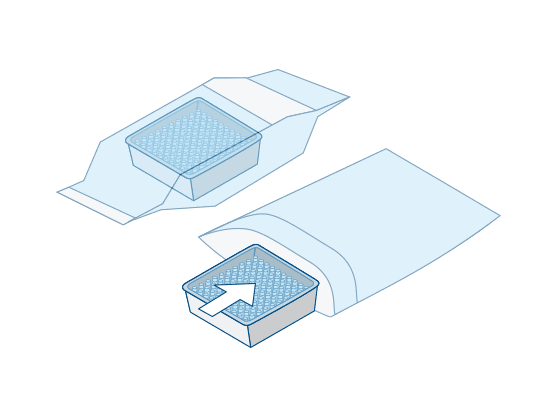

Bagging

Product packaging in bags plays an important role in product protection and in ensuring sterility. Sophisticated sealing and cutting components guarantee a high performance packaging process – from small to large format applications.

In-line printing

Products can be coded at various positions during the process. Film components or bag webs are printed with a batch code or information about the product quality. Harro Höfliger uses the popular systems thermotransfer, Inkjet or laser.

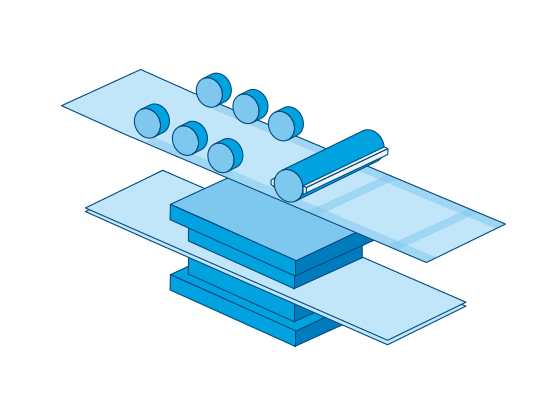

Sealing

Sealing is one of the central processes when connecting several product layers. We apply several technologies for this process. Depending on the material characteristics, we use such applications as platen sealing, roller sealing (hot and cold), pulse sealing, ultrasonic sealing or thermal sealing.

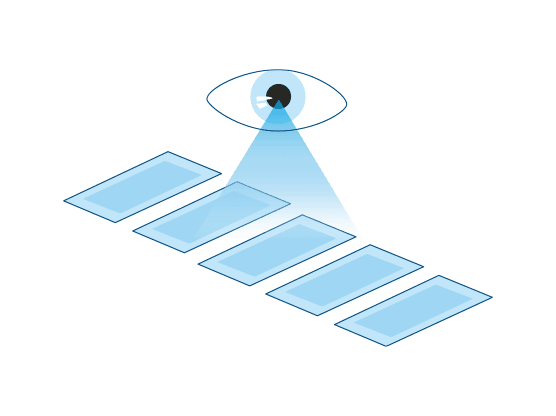

Camera inspection

Position and location accuracy, products in the sealing area, color deviations, damage or soiling to the detection of particles using sensor technology: Powerful camera systems are essential in quality inspection.