MOT Flex

Assembly platform with an innovative transport system

Description

The Flex version is based on the proven assembly platform MOT and meets the highest demands on flexibility and autonomy. The key feature is an innovative transport system which uses shuttles based on magnetic linear drives to convey the components from station to station. This enables, among other things, fast format changeovers, the assembly of different devices on one system and the distribution of the shuttles to several stations when it comes to time-critical processes.

Benefits

- Fast format changeovers

- Variable speed and acceleration between process stations

- Less demanding tasks such as presence checks can be performed simultaneously on several clustered shuttles

- Small footprint due to direct connection of trayloaders and palletizers without pucks

- High autonomy and simple operator control

- Time-critical processes can be executed individually in the required number

Technical data

- Output: up to 100 parts/min

- Stations: 12 – 50

- Workpiece carrier: 1 to 16 lanes

- Cleanroom class: ISO 7 and 8 / EU-GMP C and D

- Depending on the assembly task, the process stations are either equipped with electropneumatic or servomotor drives.

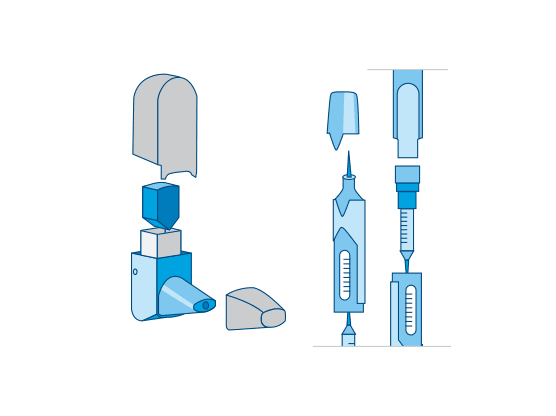

Final products

- Inhalers

- Injectors

- Nasal applicators

- Pharmaceutical devices

Periphery

- Assembly machines

- Dosing and filling machines

- Tray loader

- Marking

- Control systems

- Packaging machin

Machine features

Parts handling

Components are automatically taken out using vacs, grippers or tongs and accurately transferred. This can be performed in a linear or swivel movement. To increase the output, these systems can be set up at multiple locations so as to perform loading and unloading tasks at the same time.

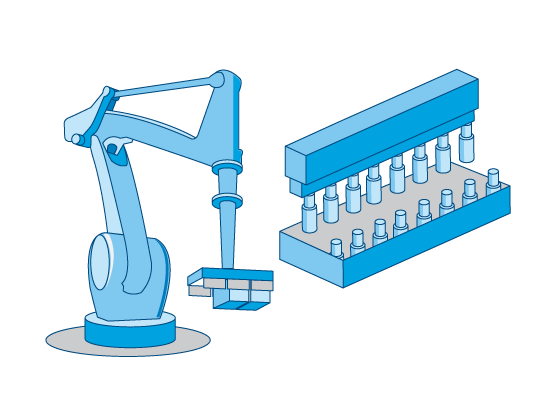

Automation

Automated logistics concepts control how product components are fed via feeding unit and regulate the transport systems within the machine. Robot and automation technology is intended to insert components into production machines and to handle them during assembly.

Joining and final assembly

Joining technology is one of the basic processes for completing assembly groups. Highly precise processes and gentle handling are perquisites to ensuring that components are reliably joined. Inspection and measuring systems guarantee the highest possible quality, even at high speeds.

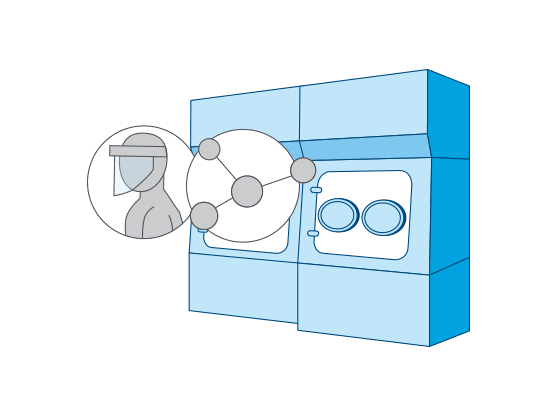

Barrier technology

Compact machine design and detailed knowledge of all processes makes Harro Höfliger a specialist in containment and barrier systems that serve to protect both the operator and the product. For ideal accessibility, ergonomic studies are performed that simulate all processes and operating steps.