MQT

Agile, servo-driven device assembly

Description

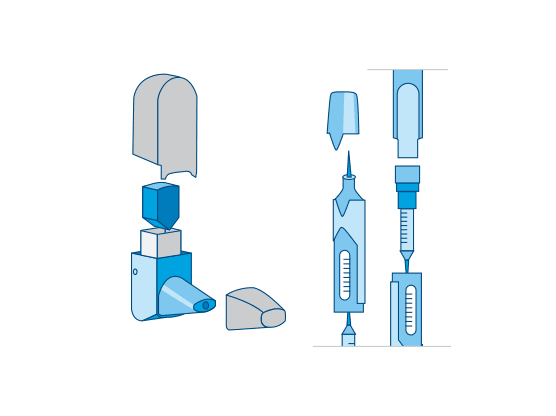

The MQT is used for the fully automatic assembly of different devices. It can be flexibly expanded to include, for example, stations for dosing, lasering and labeling. The servo-controlled drive enables maximum flexibility. Products such as autoinjectors, pens, inhalers, safety devices, patch injectors or patch pumps can be assembled and, in a separate process, marked with country-specific information. The system achieves an output of up to 160 products/minute.

Benefits

- Optimal accessibility

- Robust and highly dynamic machine platform

- Precise product transport with high machine speeds

- Wide range of camera systems that can be fully integrated

- Easy linking with additional technology platforms and packaging machines possible

Technical data

- Output: up to 60 cycles/min (1 or up to 4 lanes)

- 10 – 25 stations

- Cleanroom version: Cleanroom class 100,000 – 1,000

Final products

- Autoinjector

- Pen

- Inhaler

- Diagnostic products

- Safety devices

- Patch injectors

- Patch pumps

- Medical products

Periphery

- Assembly machines

- Dosing and filling machines

- Tray loader

- Marking

- Control systems

- Packaging machin

Machine features

Parts handling

Automated pick-up and precise transfer of components using suction cups, grippers or pincers. This can be done in a linear or swiveling movement. In order to increase capacity, these systems can be designed in a multi-unit configuration to implement, for example, loading and unloading at the same time.

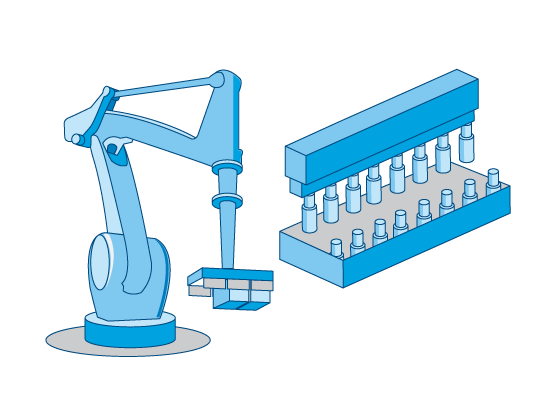

Automation

Automated logistics concepts control how product components are fed via feeding unit and regulate the transport systems within the machine. Robot and automation technology is intended to insert components into production machines and to handle them during assembly.

Joining and final assembly

Joining technology is one of the basic processes for completing assembly groups. Highly precise processes and gentle handling are perquisites to ensuring that components are reliably joined. Inspection and measuring systems guarantee the highest possible quality, even at high speeds.

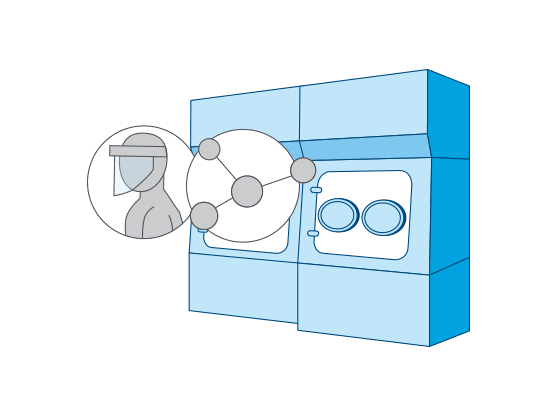

Barrier technology

Compact machine design and detailed knowledge of all processes make Harro Höfliger an expert for containment and barrier systems for operator and product protection. To ensure perfect accessibility, ergonomic studies are carried out to simulate all processes and operating steps.