TS Handling Systems

Reliable provision of components from trays, tubs and pallets

Description

The TS Handling Systems are intended for the automated loading and unloading of product components from trays, tubs or pallets. This may include components for inhalers, pens or auto- injectors, but also highly sensitive pharmaceutical components. The TS Handling Systems are available in five variants – compact, fast, flexible, in a special variant for cylindrical ampules / syringes or as a hybrid with integrated assembly and inspection processes.

Benefits

- Three basic tray loader variants (Classic, Smart, Flex) in different performance levels and sizes

- Special machines to handle cylindrical ampules / syringes from trays, or with integrated assembly and inspection processes

- GMP-compliant design

- Precise filling with servo-driven handling axes

- Ergonomic machine design and good access through side doors

Periphery

- Assembly machines

- Dosing systems

- Packaging machines

Final products

- Inhalers

- (Insulin) pens

- Auto-injectors

- Wearables

- Safety devices

Machine features

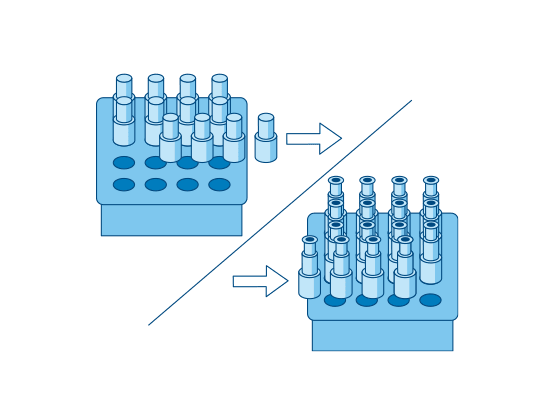

Tray handling

Trays serve to transport sensitive products. Harro Höfliger offers comprehensive solutions to load and unload trays in complete lines, for assembly projects for example. Available systems include a variety of format and performance classes for optimum synchronization.

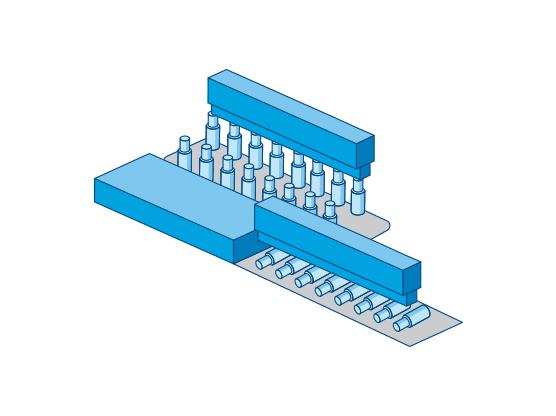

Parts handling

Components are automatically taken out using vacs, grippers or tongs and accurately transferred. This can be performed in a linear or swivel movement. To increase the output, these systems can be set up at multiple locations so as to perform loading and unloading tasks at the same time.

Product feeding

Product feeding plays a critical role in packaging machines. Harro Höfliger has a large repertoire of product handling systems. The feeding technology is configured individually depending on the requirements of the project and adjusted to the particular specifications.

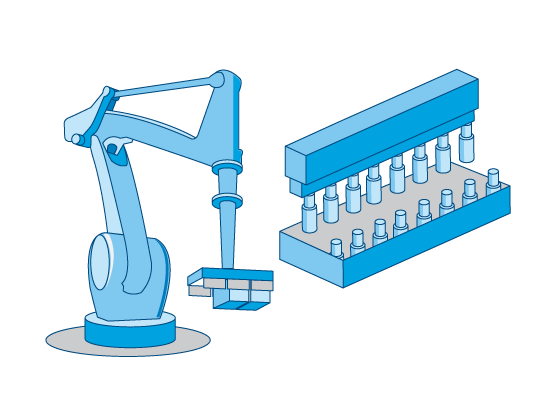

Automation

Automated logistics concepts control how product components are fed via feeding unit and regulate the transport systems within the machine. Robot and automation technology is intended to insert components into production machines and to handle them during assembly