PMK

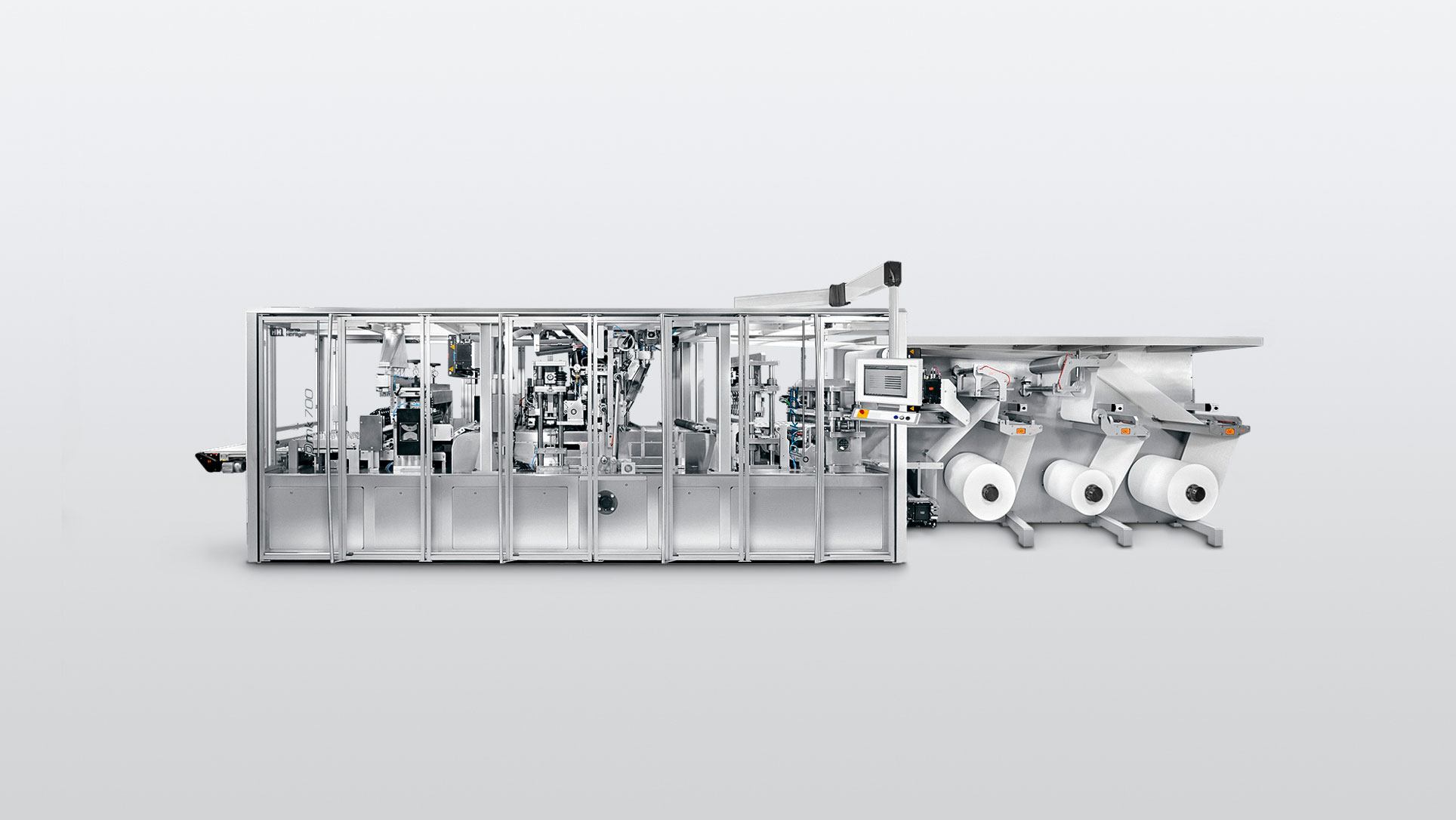

Platform for web processing for pharmaceuticals, medical and diagnostics (continuous)

Description

PMK is a freely configurable production platform for web processing. Standard core processes such as sealing, cutting and punching are combined depending on the product with individually coordinated technology modules. So, based on the PMK, for example, transdermal therapeutic system (TTS/TDS) can be produced as well as oral dissolvable films (ODF) or diagnostic test strips. The ability to replace individual modules makes it possible to easily retrofit the system to produce product variants.

Benefits

- Pharmaceutical GMP design; modular setup with a choice of different stations

- Slight and variably adjustable web tension

- Integrated film handling, punching and sealing

- Labeling, marking and printing, including inspection system

- Welding and hemming processes using thermal, laser and ultrasonic technology

- Inspection processes such as leak tightness and flow inspections, plus pressure, force, weight and torque measurements up to overall functions testing

Technical data

- Output: (typical): 200-400 products per web and minute

- Output: (maximum): 750 products per web and minute

- Common design: 1-3 webs

- A maximum of 8 webs is possible

- Web width: 150-700mm

Final products

- ODF – Oral dissolvable film

- TDS – Matrix patch standard/ special design

- TDS – Reservoir patch

- TTS – Transdermal therapeutic systems

- Diagnostic test strips and biosensors

- Classic dressing

- Medical products for dressing wounds

- etc.

Periphery

- Packaging machines

Machine features

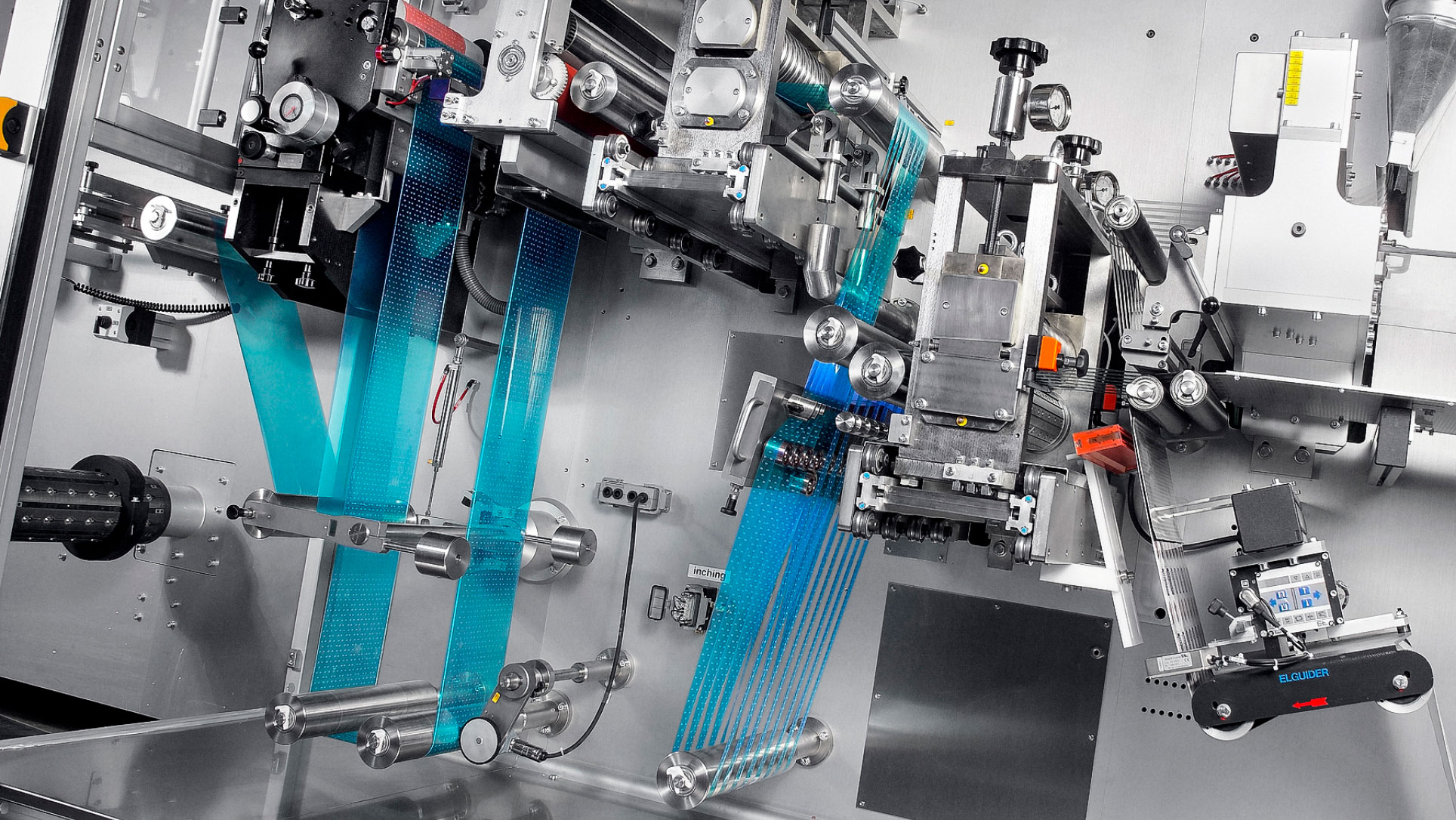

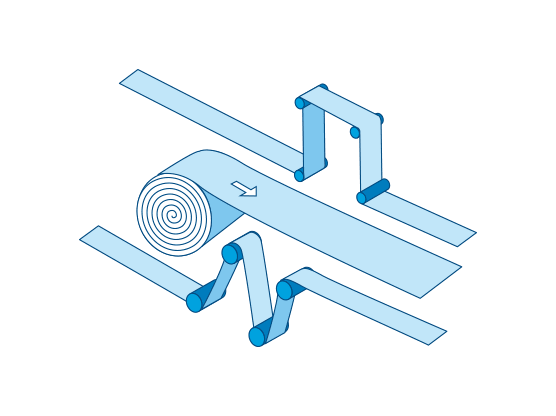

Web handling

Perfect web handling: Technical highly sensible components regulate feeding, transport and ejection of materials within the machine. Dancers, web edge controls, and winding and rewinding devices are the basic technologies for producing items such as patches.

Punching

The punching processes in a web processing system require the highest degree of precision and quality of raw materials in order to achieve the high outputs required during continuous operation, while also guaranteed the necessary accuracy. To achieve this, we use solid punching tools and die punching, in our machines.

![[Inhalt: Englisch] Siegeln und Verschlusstechnik [Inhalt: Englisch] Plattensiegelung, Rollensiegelung (heiß und kalt), Impulssiegelung, Ultraschallschweißen oder Thermisches Siegeln kommen – je nach Produkt – bei der Verbindung mehrerer Produktlagen zum Einsatz.](/fileadmin/user_upload/maschinen/piktos-prozesstechnologie/Maschinen-Prozesstechnologie-Siegeln.png)

Sealing

Sealing is one of the central processes when connecting several product layers. We apply several technologies for this process. Depending on the material characteristics, we use such applications as platen sealing, roller sealing (hot and cold), pulse sealing, ultrasonic sealing or thermal sealing.

![[Inhalt: Englisch] Kamerasysteme zur Qualitätsprüfung [Inhalt: Englisch] Kamerasysteme sind essentiell in der Qualitätsprüfung](/fileadmin/user_upload/maschinen/piktos-prozesstechnologie/Maschinen-Prozesstechnologie-Kamerakontrolle.png)

Camera inspection

Position and location accuracy, products in the sealing area, color deviations, damage or soiling to the detection of particles using sensor technology: Powerful camera systems are essential in quality inspection.

Applications

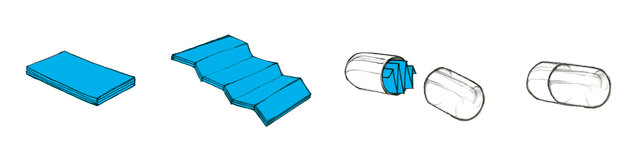

High-performance production of a

special capsule solution

With the Accordion Pill®, Intec Pharma has developed an innovative capsule platform that provides continuous drug release. The manufacturing technology for the product was supplied by Harro Höfliger.

High-speed line for TTS/TDS products

When it comes to the production of patches for the treatment of asthma and pain Nipro Patch relies on Harro Höfliger’s many years of expertise in web converting as well as in transdermal systems.