Machines and technology turning ideas into products.

With our large portfolio of standard machines and platform techniques, we offer solutions for individual process steps or for the complete production line. Customized solutions – precisely what you require for your level of mechanization. Our machines and technologies cover every development stage of your product, from the lab to batch series or high-speed production – we always pursue the goal of providing scalable, reliable processes throughout your entire development.

We adapt all processes to your specific requirements. Our experts combine proven basic processes and newly developed stations to find tailor-made solutions. In addition to the wide variety of different technologies of our company, we also have a network of specialized technological partners. This allows us to provide you with high-tech solutions that can manufacture the products of tomorrow today.

Machines & Technologies

Web processing

Modular platforms for the manufacture of multi-layer products from roll material for the medical and pharmaceutical industries.

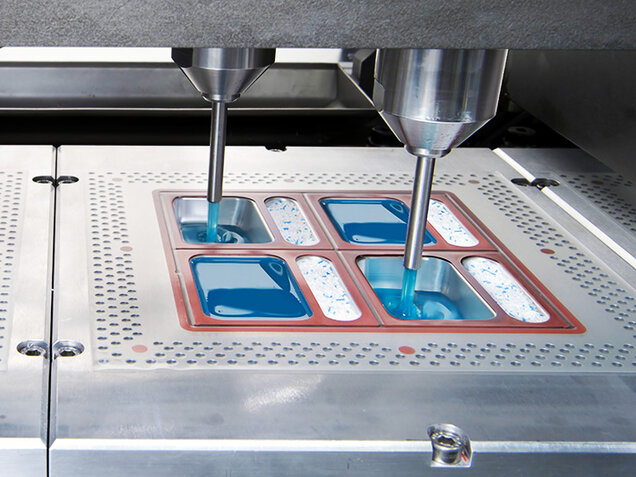

Dosing & filling

Mature, scalable dosing processes with the appropriate dosing system for every medium.

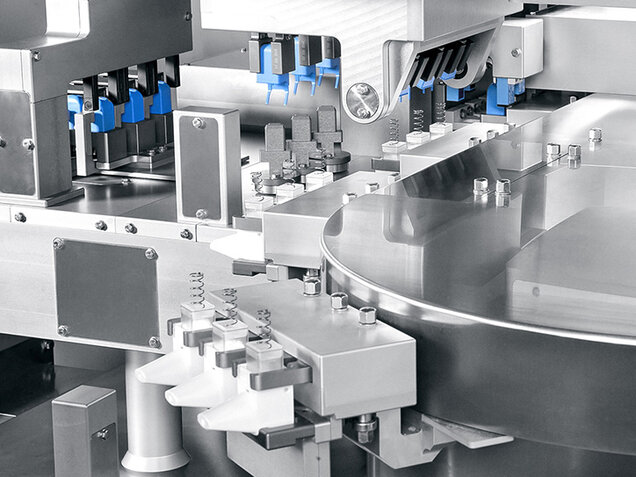

Production of portion packs

Forming, filling, sealing and punching of portion packs from small batches to large-scale production.

Mass control

Control systems that guarantee exact dosing and process reliable detection of faulty products.

Production of suture material

Automated winding of surgical suture material.

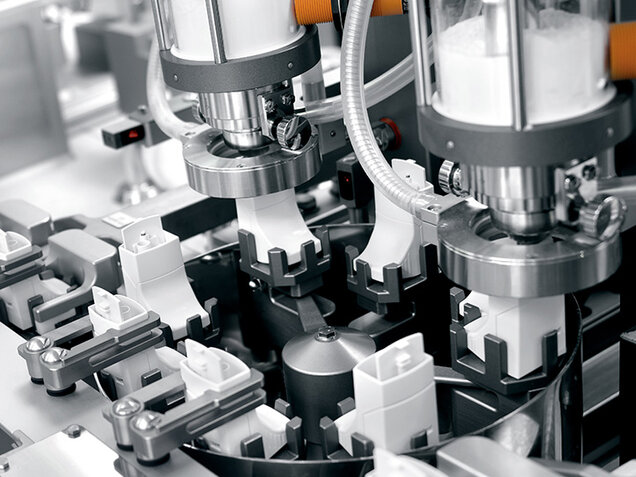

Product assembly

Modular technology for efficient pre- and final assembly of pharmaceutical and medical products.

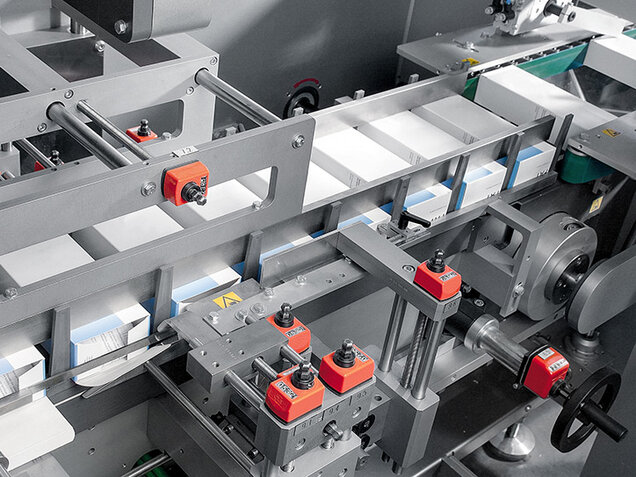

Packaging

Efficient solutions for your specific packaging needs, from stand-alone machines to turnkey packaging lines.

Process quipment

Barrier technology

Customized barrier systems that provide reliable protection for operators and products.

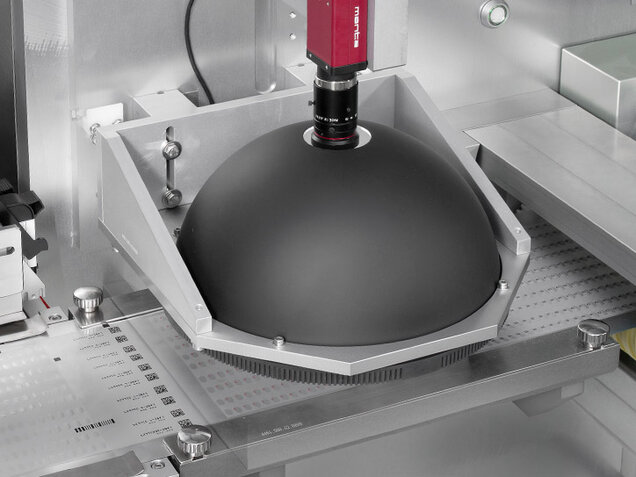

Quality control

Guaranteed process quality thanks to camera systems and precise measurement technology.

News and events

Assembly Forum in Jakarta

The event revolves around current developments in the field of medical devices.

Rescon Summit 2024

27.06 - 28.06.2024

Barcelona

Spain