Technologies for high-quality diagnostic products

Whether it is film-based products, such as diagnostic strips or cuvettes, PCR strips, test dispensers or point-of care systems (lab-on-a-chip, lab-on-a-disc) – Harro Höfliger offers a wide range of platforms for the assembly and manufacture of diagnostic products. Highest precision during all processes and in-process controls ensure that all testing devices provide utmost reliability. The pipetting of suspensions and liquids, as well as the microdosing of liquids and powder, pellets or lyophilisates are handled by our proven dosing systems. Assembly in a clean room environment with integration of different protection concepts is our daily business. Our modular concepts enable us to cover our customers’ entire process chain from complex filling, sealing, handling, assembling to the final packaging of diagnostic products.

- High-precision automation technology for assembly of diagnostic products

- Micro-filling and dosing technologies for liquids, suspensions and powder

- High speed foil processing for the conversion of multi-layer products

- Expertise in laminating, coating, cutting and sealing of foil materials

- Various protection concepts for assembly in a cleanroom environment

- Consistent scaling from proof-of-principle to high-speed production

- Support provided by our services such as Pharma Services, Engineering and Innovation Services (EIS), Device Services and Validation Services

Our expertise

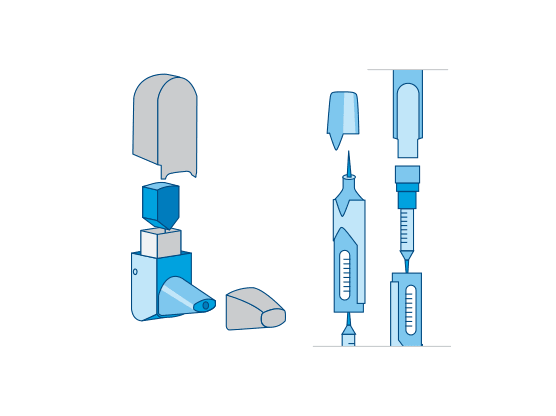

Assembly of complex devices

Sophisticated diagnostic products require careful assembly processes to ensure functionality and reliable results. Based on our flexible modular systems, we always find the perfect technical solution tailored to your diagnostic product.

Microanalysis systems

We offer flexible filling and sealing modules for the production of diagnostic test carrier systems such as lab-on-a-chip or lab-on-a-disc. The reagents are dosed in pipetting stations. In the sealing station, the test carriers are sealed tightly with glue-coated or thermal sealing films.

Handling of lyophilisates

Lyophilized pellets (lyo bead pellets) are ideally suited for diagnostic test carrier systems due to their storage stability. With the Lyo Bead Dispenser, the sensitive pellets can be dosed into the containers with pin-point accuracy, without mechanical stress or electrostatic charging.

Products

Machines and categories

Applications

Lab-on-a-chip production for rapid tests

So-called mini labs make it possible to analyze samples at the “Point-of-Care”. Harro Höfliger supplied a filling and sealing station for the production of test elements at Hahn-Schickard in Freiburg.

Gentle handling of lyo bead pellets

For the handling of lyophilisates, Harro Höfliger offers a unique automated solution – the Lyo Bead Dispenser. The freeze-dried pellets are safely conveyed and accurately dosed via air flow.