Reliable packaging of surgical suture material

Harro Höfliger’s full expertise goes into every wound thread, every easy-to-handle tray, every specially shaped blister pack and, finally, every perfectly packaged suture material. With our assembly and packaging machines, we offer sophisticated solutions for test setups, low-speed machines and high-speed production. We don’t leave anything to chance here: our experts will support and advise you with their know-how and experience in each of your product phases.

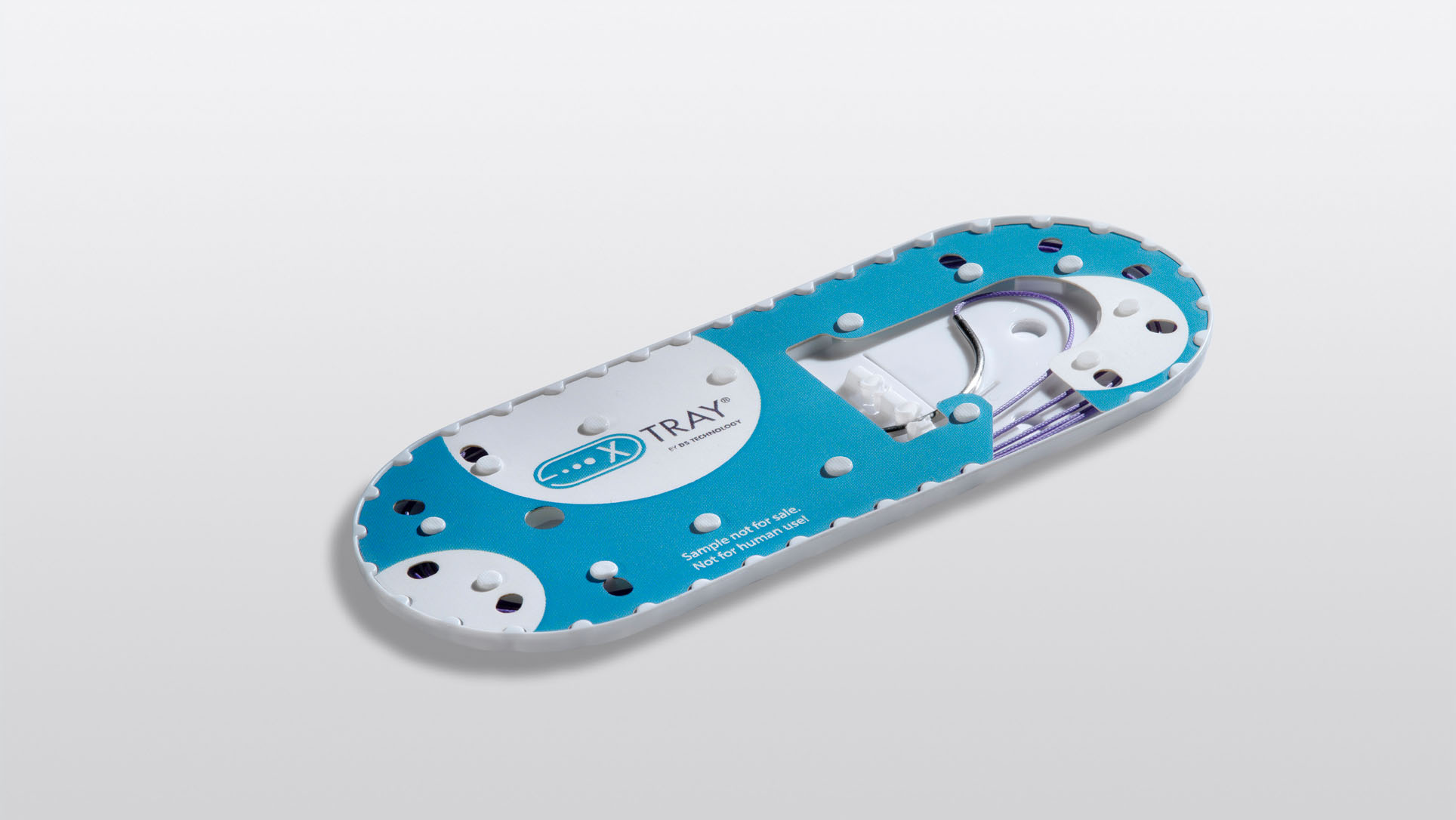

Harro Höfliger also supplies the complete technology for the XTray® licensed by DS Technology. With this device, which can be used for 80 percent of all needle-suture combinations, customers can launch their product on the market without any development effort of their own.

- Winding, forming blisters, inserting trays, applying covering film

- Printing and process control in-line

- Database connection

- Winding, printing and process control in-line

- Solutions for various needle geometries, thread qualities and thread sizes

- XTray® from DS Technology

- Plastic trays in numerous designs

- Turnkey solutions for production and packaging

Our expertise

Winding

Accuracy remains the highest priority when the needle is locked onto the tray and while the thread is wound. Thanks to our cutting-edge technologies and individually coordinated production steps, only perfectly stocked trays continue on to the subsequent blister packaging.

Blistering and packaging

The suture material is packaged into blisters made from shaped aluminum with two chambers, one of which holds the tray. The second is for sterilization: It contains a covering film with a Tyvek window through which the gas can penetrate during sterilization. It is subsequently separated in the sealer/blanker machine.