Systematically good service

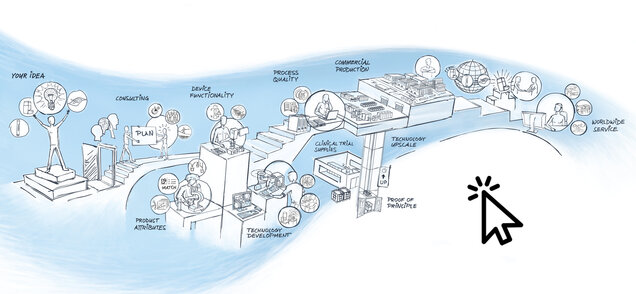

Comprehensive, integrated services – this is part of Harro Höfliger’s ALL YOU NEED standard. Our support begins early on: Our specialists are happy to advise you right from your initial product idea. Also available to you right in the early project phases are a state-of-the-art laboratory for comprehensive analyses and conditioned cleanrooms for running tests.

Starting from the development of optimum processes to their technical implementation and subsequent validation right up to the successful commissioning of your machine or the launch of your product onto the market – we accompany you every step of the way and well beyond that. You can rely on our experts – during the entire life cycle of your machine and your product.

- Consulting – advice and expertise regarding product ideas, technology and processes

- Pharma Services – product characterization and technical sample production under production conditions

- Engineering & Innovation Services – technical development of new processes and procedures

- Device Services - support in developing and optimizing your devices

- Validation Services – risk-based approach to ensuring product quality

- Project management – internal and external project implementation and communication

- Customer Service – comprehensive support for machines and production

Find out how we can support you from lab to production