SSP2

Small Scale: The small batch machine for micro-dosing powder into inhalation blisters (intermittent)

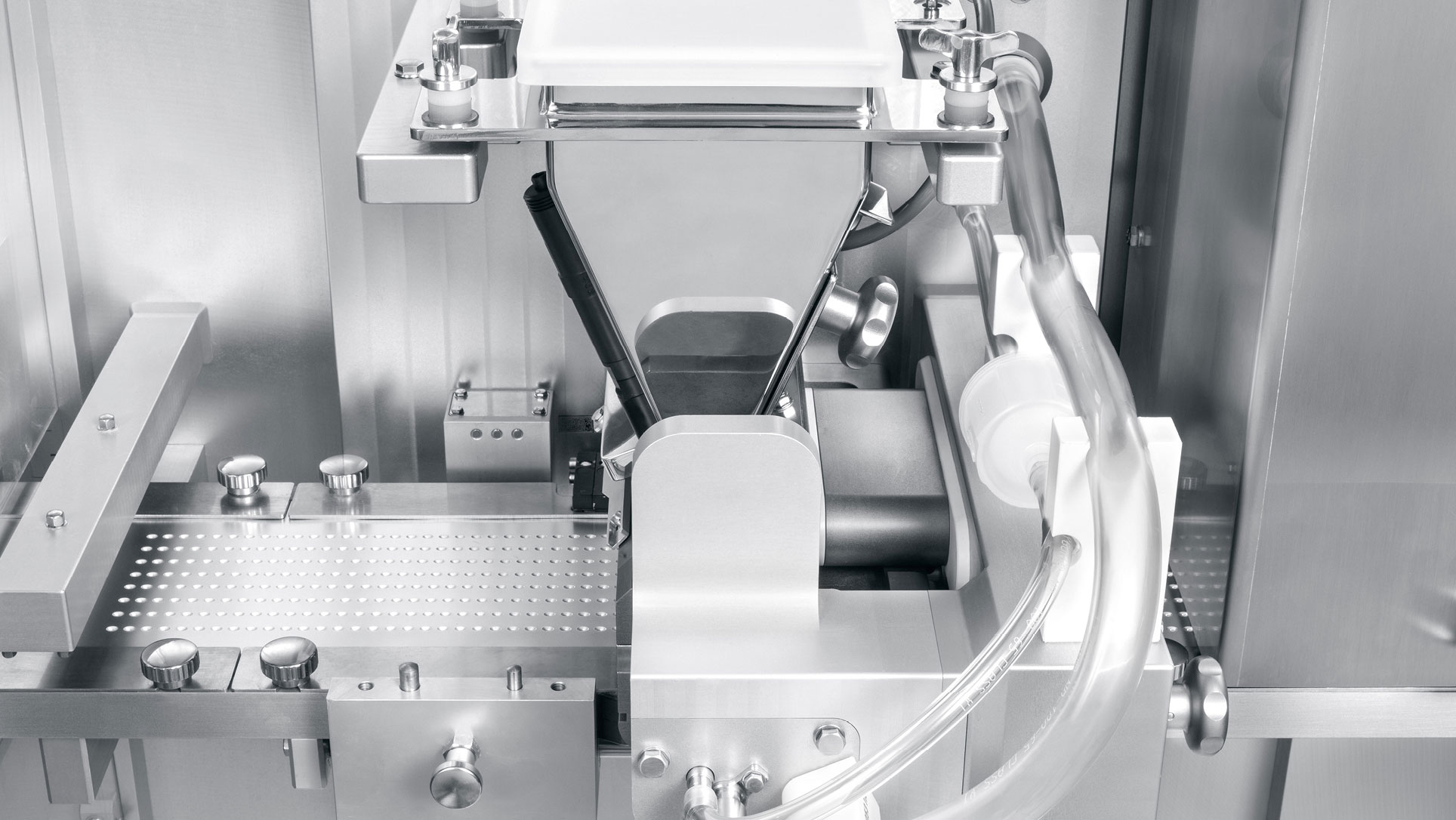

Description

The SSP2 forms, fills and seals blister strips and allows a fully-automatic production. Filling can be done alternately either via drum dosage to partially fill cavities or via membrane dosing for complete filling. The blister packaging can be customized as wound double strips or sheared single strips, mounted by down-stream machines and then finally packaged.

Benefits

- Separate production area with good accessibility

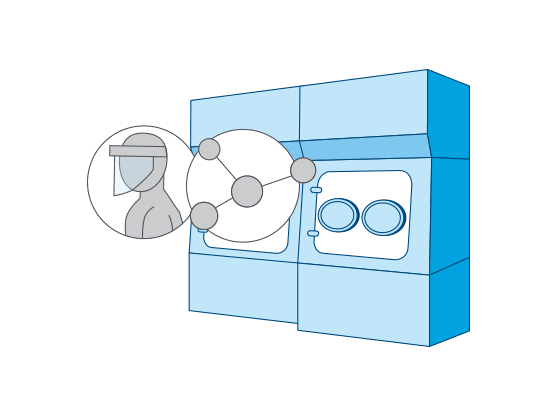

- Integrable containment for operator protection while processing highly-active and toxic products

- Continuous inspection of the product quality

- Ease of use and easy maintenance

- Compact design with minimal set-up space

Technical data

- Drum dosing: 144 Fill volumes/min (24 cycles/min.)

- Membrane dosing: 900 Fill volumes/min (15 cycles/min.)

- Web width: 150 mm

- Output: up to 11 strips/min (blister strips with 60 cups)

Final products

- Aluminum blister strips for inhalers

Periphery

- Mounting machine for inhalers

- Final packaging machines

Machine features

Forming blisters

Minimum quantities of active-ingredient powder are dosed into blister cavities for dry powder inhalers. Plastic forming of these tiny cavities is achieved through thermal forming (PE film) or cold forming (aluminum film).

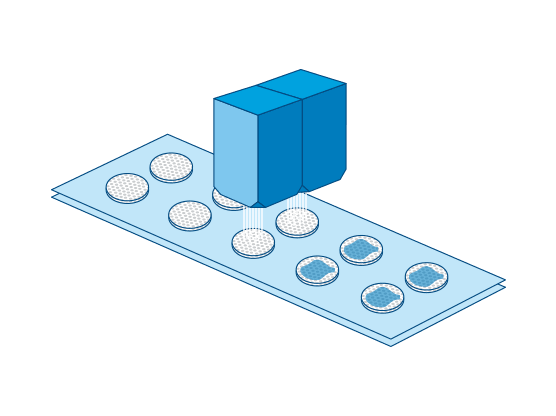

Filling blisters

The powder filling module can be equipped with a drum filler or with a membrane filler. The drum filler produces partially filled cavities whereas membrane filler is filling the blister cavity to 100%.

Closing blisters

Filled blisters are closed with covering or forming film. The sealing tools used can be configured by adjusting pressure, temperature and time separately for each material.

Barrier technology

Compact machine design and detailed knowledge of all processes makes Harro Höfliger a specialist in containment and barrier systems that serve to protect both the operator and the product. For ideal accessibility, ergonomic studies are performed that simulate all processes and operating steps.