Future-oriented products for patient care

Manufacturers of ostomy bags with convex and non-convex barriers plus catheter products continuously refine their products. This is to ensure the highest possible level of comfort and safety for patients with a stoma or a voiding dysfunction. Thanks to our solid expertise in the field of patient attached devices (PAD), stoma bags, intermittent catheters and accessories, we offer state-of-the-art solutions for the most complex manufacturing processes and production. Depending on requirements, both open and closed multi-layer stoma bags can be produced and high-tech filters can be integrated. The modular design of each line enables our customers to react flexibly to future developments.

- Extensive expertise in ostomy and continence care products

- Production platform for closed and open drainable pouches

- Support from product development through PoPs and pilot scale to production

- Modular system for highly flexible production

- Reliable process and in-line control of critical areas

- Turnkey solutions for production and packaging

- Support provided by our services such as Pharma Services, Engineering and Innovation Services (EIS), Device Services and Validation Services

Our expertise

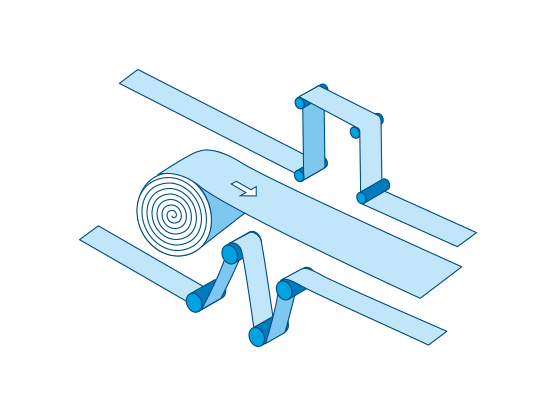

Web material handling

In the manufacturing of multi-layer products, what is essential is to be fully knowledgeable of the properties and behavior of the individual web materials. With our many years of experience we offer individual solutions using modular technologies, unique in their combination and based on extensive PoP.

Punching

The punching processes in a web processing system require the highest degree of precision and quality of raw materials in order to achieve the high outputs required during continuous operation, while also guaranteed the necessary accuracy. To achieve this, we use solid punching tools and die punching, in our machines.

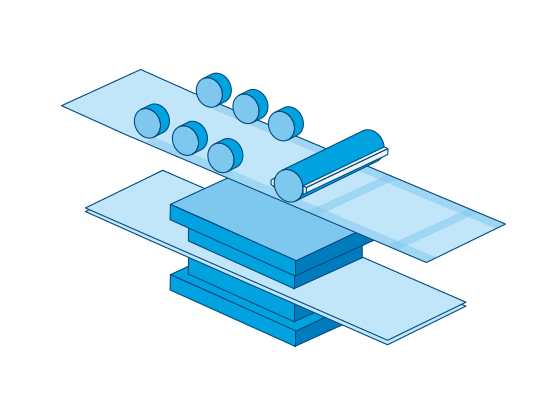

Sealing

Sealing is one of the central processes when connecting several product layers. We apply several technologies for this process. Depending on the material characteristics, we use such applications as platen sealing, roller sealing (hot and cold), pulse sealing, ultrasonic sealing or thermal sealing.

Products

Machines and categories

Applications

Navel patch heals abdominal pain

The Shanxi Yabao Pharmaceutical Group produces homeopathic patches for the Chinese market. The “gingerbread” patch is manufactured on a Packing and Four-Side Sealing Machine from Harro Höfliger.