MKT

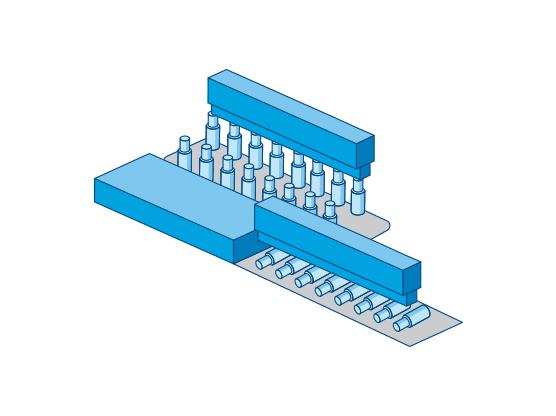

Universal: The reliable cartoning machine for highest performance

Description

With an output of up to 150 folding cartons per minute, the intermittent MKT offers maximum productivity – and a very small footprint. The quick and easy format change with plug-and-play functionality and an ingenious product transport system make it extremely flexible, so a wide variety of products can be packaged with short setup times. Decentralized servodrive control also ensures that the machine runs quietly and smoothly even at high speeds. The low maintenance requirement increases efficiency further.

Benefits

- Modern, robust construction in GMP-appropriate design.

- Optimum accessibility

- Rapid size changes with reproducible settings

- Set-up of all current market folding box closing variants as well as customized closing options

- Ability to set up two closing variants on one machine

- Highest flexibility with highly dynamic servo drives

- Product insertion from the rear (side-loading) ensures a clear machine front and optimal accessibility of the packaging area

Technical data

- Output MKT 7,5″: up to 100 folding boxes/min.

- Output MKT 5″: up to 150 folding boxes/min.

Final products

- Pharmaceutical products

- Chemical-technical products

- Cosmetic products

- Any product from fragile to durable

- Folding boxes with highest quality requirements

Periphery

- Assembly systems

- Web processing machines

- Film forming machines

- Dosing and filling machines

- Inspection systems

- Serializing

Machine features

Cartoning

Cartoning with our packaging machines features reliable, active opening of folding boxes even for demanding cross-sections, reliable processes when inserting product and package insert, and sophisticated technology for customized folding box closing options.

Product feeding

Product feeding plays a critical role in packaging machines. Harro Höfliger has a large repertoire of product handling systems. The feeding technology is configured individually depending on the requirements of the project and adjusted to the particular specifications.

Brochure

Brochures are folded to the suitable sizes using standardized systems and then inserted into the package. The process gets more demanding if variable data is printed in them and they must be verified by visual inspections. The packaging insert is critical to ensure preparations are used safely.

Serializing

Our packaging machines can be easily equipped with serializing processes for the benefit of quality assurance and to increase protection from counterfeiting medicine. In the process, folding boxes are each marked individually and recorded by an image inspection system.

Applications

side-loading/top-opening

Packaging products quickly and attractively – horizontal cartoning units are a convenient solution for safe, customer-friendly packaging of several components in top-opening boxes.

Labelling and packaging of eye drops

Harro Höfliger produced a labeling and packaging line for Pharma Stulln – a GMP-compliant production line – within a very tight deadline. The limited space available required special line planning.