FRT

Platform for rapid and space-saving production with an integrated dosing process

Description

The flexible rotary indexing table is the perfect platform for product filling and an assembly platform for products with a limited number of individual components and processes. Since dosing and verification processes are positioned in a compact arrangement, the platform requires only very little space. The rotary indexing machine FRT can be equipped with one or several turrets.

Benefits

- Fully automatic and semi-automatic versions possible by integrating manual workstations

- Sophisticated dosing methods and control systems

- High availability and (high) speed while requiring little space

- Integrated containment for operator protection when processing highly active and toxic substances

- Easy linking with further technology platforms and packaging machines possible

Technical data

- Output: up to 60 cycles / minute

- Version: 1 to 12 lanes

- Cleanroom version: cleanroom class up to A 100,000 - 100

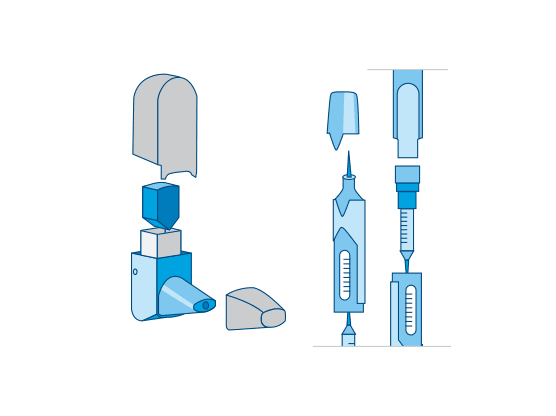

Final products

- Inhalers

- Devices

- Cartridges

- Powder reservoirs

Periphery

- Assembly machines

- Dosing and filling machines

- Feeding technology

- Product labeling

- Control systems

- Packaging machines

Machine features

Parts handling

Components are automatically taken out using vacs, grippers or tongs and accurately transferred. This can be performed in a linear or swivel movement. To increase the output, these systems can be set up at multiple locations so as to perform loading and unloading tasks at the same time.

Dosing processes

Depending on the quality of the ingredient, a variety of dosing processes can be used for powder, solids or liquids. Harro Höfliger’s core competencies involve developing solutions for and integrating the best possible dosing methods.

Joining and final assembly

Joining technology is one of the basic processes for completing assembly groups. Highly precise processes and gentle handling are perquisites to ensuring that components are reliably joined. Inspection and measuring systems guarantee the highest possible quality, even at high speeds.

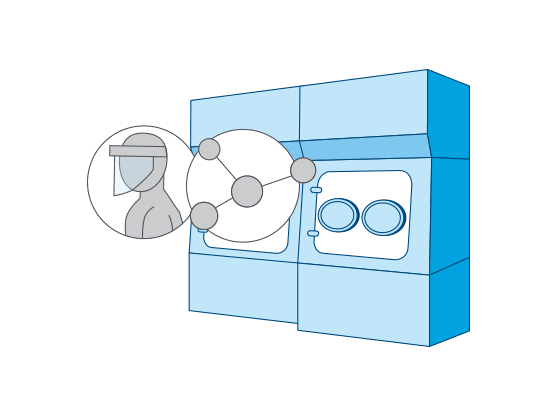

Barrier technology

Compact machine design and detailed knowledge of all processes makes Harro Höfliger a specialist in containment and barrier systems that serve to protect both the operator and the product. For ideal accessibility, ergonomic studies are performed that simulate all processes and operating steps.