PFM-K

Production machine for manufacturing portion packs (continuous)

Description

PFM-K is intended for manufacturing single and multi-chamber products made of PVOH or plastic. A chain transport moves the format plates through the machine. After deep pulling of the film using a vacuum or a cold/warm forming process, the chambers are filled with powder and/or liquid. The chambers are then sealed with cover film and cut or punched out of the format plates.

Benefits

- Extremely high output (HS model)

- Transport via format plates with chain transport

- Customized product carriers

- A variety of dosing systems for liquid and/or powder filling

Technical data

Output:

- HS approx. 800 - 1800 products/min.

- MS approx. 300 - 800 products/min.

Final products

- Portion packs for customer care and medical products

- Dishwasher pads

- Dishwasher tabs

- Coffee pads

- Contact lenses

Periphery

- Packaging machines

Machine features

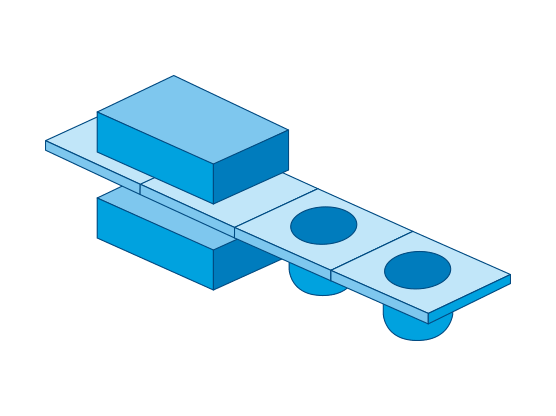

Forming

A variety of methods are available for the forming process. In addition to thermoforming, deep drawing or vacuum forming is applied. These processes are integrated into the system platforms developed by Harro Höfliger with the product-specific function stations.

Liquid dosing

Dosing systems for liquids are used in the form of modules in pharmaceutical and medical production platforms at Harro Höfliger. This way, custom project requirements can be tailored as needed. The systems can be variably adapted to the defined performance specifications.

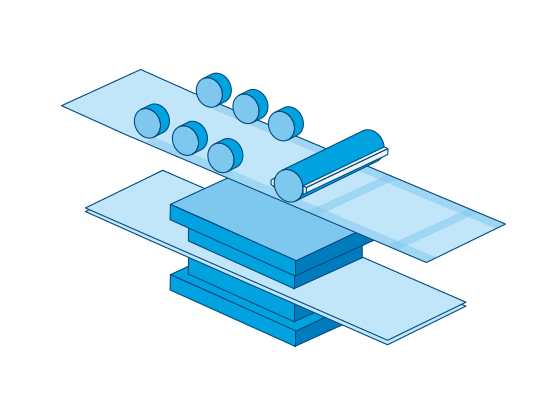

Sealing

Sealing is one of the central processes when connecting several product layers. We apply several technologies for this process. Depending on the material characteristics, we use such applications as platen sealing, roller sealing (hot and cold), pulse sealing, ultrasonic sealing or thermal sealing.

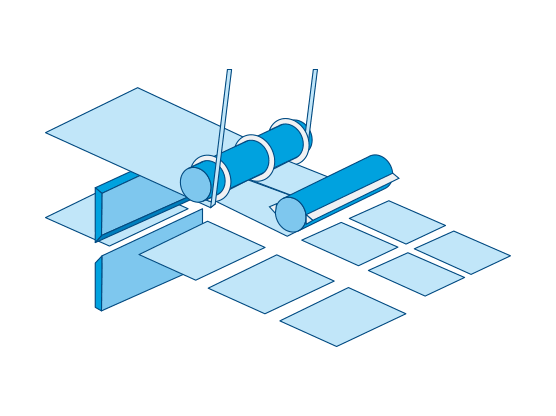

Cutting

Cutting processes require the highest degree of precision and quality of the raw materials in order to achieve the high outputs required during continuous operation, while also ensuring the necessary accuracy. Applied here are, for example, cutting cylinders and sleeves, flying blades, steel band cutter, longitudinal drum cutter or laser contour cutter.