MCP

End of line: The efficient Casepacker for shipping boxes (intermittent)

Description

In the MCP Casepacker, folding boxes are fed onto a single track, grouped and stacked. The boxes can be packed either via side loading or via wrap-around. Serializing functions make it possible to detect the separate folding boxes and to label each individual shipping box.

Benefits

- High performance end packaging system

- Optimum accessibility

- Rapid size changes with reproducible settings

- Large range of formats of the packaging sizes

- Consistent operating concept with touch panels

- Extremely small footprint

Technical data

- Output: up to 10 boxes/min

Periphery

- Assembly systems

- Web processing machines

- Film forming machines

- Dosing and filling machines

- Packaging machines

- Handling systems

Machine features

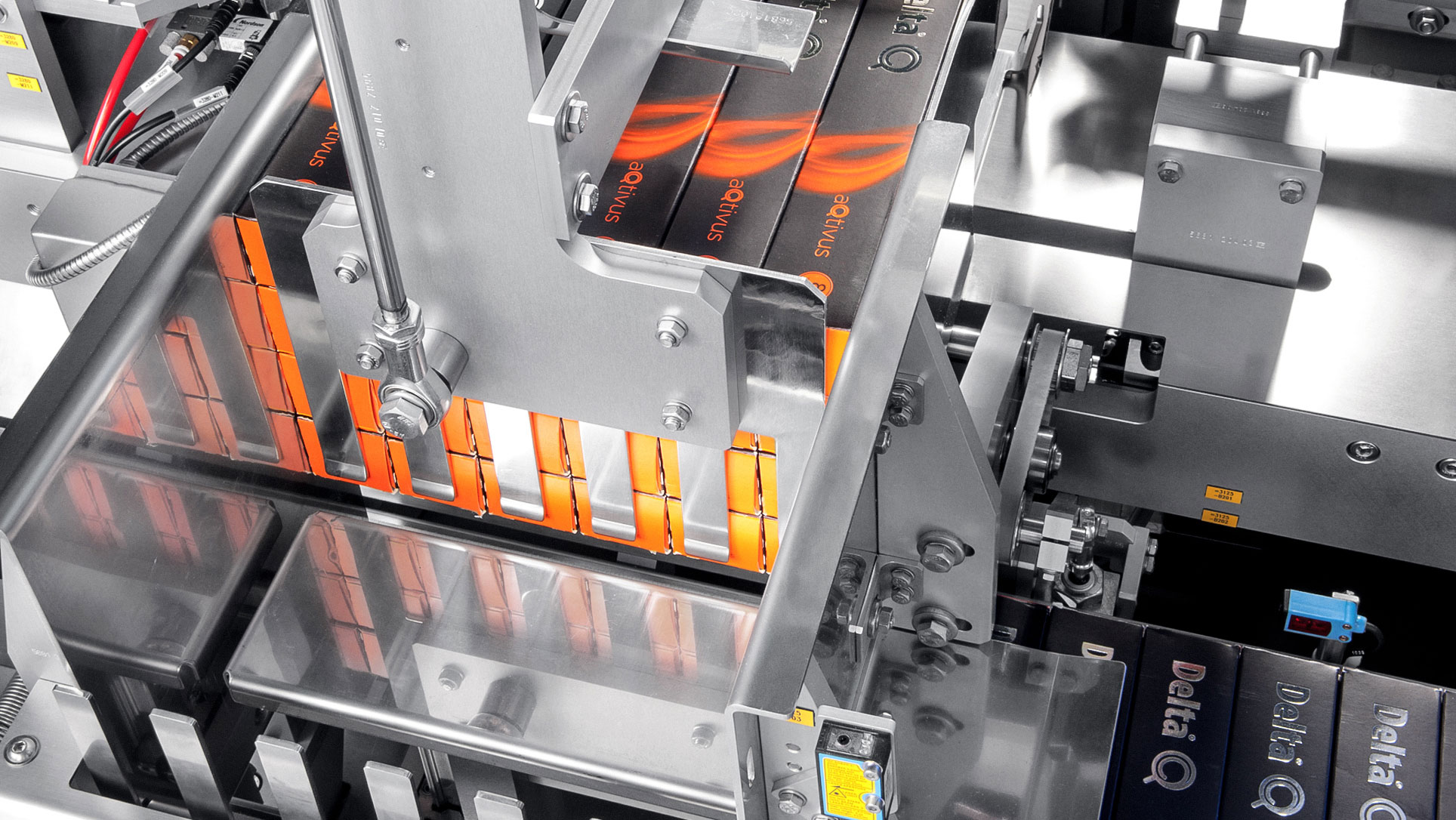

Multi-packaging

The last link in our assembly and packaging lines is the multi-packaging. Here, folding boxes are grouped, stacked and packaged for shipping. This is done either via side-loading in upright cartons or via wrap-around technology.

Automation

Automated logistics concepts control how product components are fed via feeding unit and regulate the transport systems within the machine. Robot and automation technology is used to insert components into the packaging machine.

Sealing

All common cartoning closing methods are used in Harro Höfliger packaging machines. Whether closing the box with carton flaps, by applying an adhesive, by placing a cover on it or with sealing wax. The Höfliger experts can even find the ideal technical solution for custom special closing methods.

Serializing

Our packaging machines can be easily equipped with serializing processes for the benefit of quality assurance and to increase protection from counterfeiting medicine. In the process, folding boxes are each marked individually and recorded by an image inspection system.

Applications

Labelling and packaging of eye drops

Harro Höfliger produced a labeling and packaging line for Pharma Stulln – a GMP-compliant production line – within a very tight deadline. The limited space available required special line planning.

Efficient packaging of syringe sets

The demand for an oncological drug is increasing. AstraZeneca has therefore decided to automate the packaging processes with a turnkey line.